Langley, BC—The phrase that best describes San Group, with its head office here, is “FROM HARVEST TO HOME.” In fact, that phrase has become the mantra for brothers Kamal Sanghera and Suki Sanghera, both Executive Directors, as they pride themselves in not only planning every step from harvesting the trees to sawmilling, remanufacturing, sales and shipping but also in jumping right in and getting their hands dirty to complete a task so that the next stage is set.

Two more words that could describe San Group are “growing” and “expanding.” “With a renewable resource like lumber and taking it a few steps further than it has ever been, we evolved the business to take on the future in a smarter way,” stated John Langstroth, senior vice president.

Suki Sanghera noted, “In the markets, you have to grow, or you will not fit right. Everybody wants something new. So, you have to do something new monthly or yearly.”

That’s what San Group is doing, expanding into new markets and acquiring the facilities and equipment to provide those new products.

San Group is a vertically integrated forest products company, operating in coastal British Columbia. San Group’s operations include timber harvesting, saw milling, lumber re-manufacturing, value added lumber manufacturing, global distribution sales and consumer retail sales via San Cedar Direct stores. While selling rough sawn timber directly from the sawmill is and always will be the biggest avenue of moving wood products, San Group’s other products include engineered wood and items such as fascia, veneer and finger joint.

San Industries Ltd., a remanufacturing facility in Langley, BC, was San Group’s first plant. San Group has continued to improve that facility.

In 2017, San Group purchased the Coulson Sawmill, now identified as San Port Alberni “A Mill.” The design and purpose of the original Coulson sawmill was to break down larger grade logs and timber to service the Japanese export market. While the original purpose may have changed to accommodate today’s marketplace, the footprint left behind by Wayne Coulson to produce the finest boards and timber remains intact.

Nestled in mid-Vancouver Island, the ecologically rich area of Port Alberni, BC has access to some of the world’s finest timber which San Group manufactures not only to structural and appearance products but also some of the finest pattern and finish type products. Vancouver Island Softwood species that comprise the input log diet for San Group include Western Red Cedar, Hemlock, Douglas Fir, Sitka Spruce, Yellow Cedar, Alder and Western White Pine.

Since the acquisition of the San Port Alberni “A Mill,” brothers Kamal and Suki Sanghera have sought to expand San Group operations in Port Alberni and support the community that eagerly welcomed them with open arms.

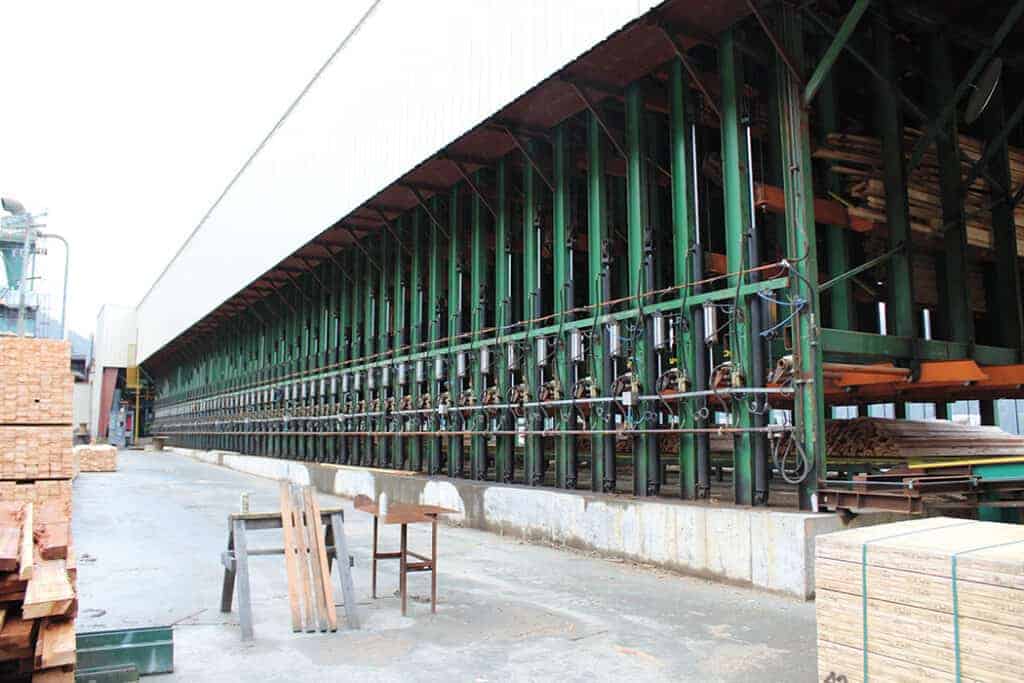

San Group has transformed part of the “A Mill” building from an engineered product facility to a mill for smaller logs, called “B Mill.” The smaller logs are cut up in an efficient and quick way and are transported to a 60-bin system to separate the lumber.

The company also has established San Forest Products Ltd. and San Forest Specialty, both in Port Alberni. Suki Sanghera said, “San Forest Products Ltd. is our Advanced Wood Value Added Manufacturing Plant. The new plant takes in over 300,000 square feet. It manufactures the world’s most premier value-added lumber products which are exported globally and sold domestically at San Group’s San Cedar Direct stores, located across Western Canada.

“San Forest Products is our newest mill with production capacity of 35 million board feet, strategically positioned as a value-added mill designed to seamlessly flow into our vertically integrated business model,” Suki Sanghera continued. “The new Value Added mill with over 25 different machine centers has the ability to not only extract high value products from low grade lumber but also finish products in a way that increases the value exponentially. It is safe to say, specialized lumber production is at the heart of San Forest Products, and we welcome the most unique orders to service the global market as one of the world’s most premier value-added mills.”

San Group also purchased Acorn Forest Products Ltd., a log-to-lumber facility, in Delta, BC from Interfor. “Traditionally that mill was engineered primarily as a Japanese-destination product, but the current shift in demand for product in Japan has enabled us to expand to other markets,” Langstroth remarked. “By doing so, we’ve really put together some very forward-business in new markets that was previously untapped by that whole facility.

“The Coulson (A Mill) original sawmill is designed for a bigger grade log, so it is designed to extract the highest grade out of each log possible,” he continued. The large log line and the small log line, in Mill A and Mill B respectively, feed the engineered and reman facilities. “So, we actually have the smallest footprint of any log-to-lumber-to-finish product turnaround in all of British Columbia,” he stated. “Where we cut the logs, where we take the product from the logs and further remanufacture it and add value to it is less than seven miles from turnaround. We are using a product that is renewable and we’re trying to produce finished products in the most earth friendly way.”

New equipment has been added to San Group’s plants. At the Acorn mill, dry kilns had lain dormant for 10 years. Those kilns are close to being operational again, “which will further put us in control of another part of the manufacturing process,” Langstroth said. Equipment includes stacker/sort, moulder, resaw, lamination line, dry kilns, high speed planer and a paint/stain line.

“We have made some very well-planned position additions to our sales team, those that focus on North America and European markets,” Langstroth observed. “We are selling to over 40 countries presently and we are pretty proud of that. In any corner of the world that you can go to, you will probably see some San Forest products.”

In fact, San Group has acquired a deep-water dock, which is in development. When useable, this port will allow San Group to ship anywhere in the world.

The sales team at San Group is ready to look after all of your lumber needs.

The team includes:

John Langstroth – john@sangroupinc.com – Senior Vice President

Adam Hazelwood – adam@sangroupinc.com – North American Sales Manager

Tyler Moore – tyler@sangroupinc.com – Vice President of Export Sales

Jim Brindle – jim.brindle@sangroupinc.com – White Wood Sales Manager.

Bruce Molander – bruce@sangroupinc.com – Japan Sales Manager

Addison Ross – addison@sangroupinc.com –Sales Oceania and North America

Peter Zhao – peter@sangroupinc.com – Sales Asia

Ryan Hagen – ryan@sangroupinc.com – North American Sales

As proud Canadians the goal is to continue to evolve, expand, and in so doing create even more family supporting job opportunities. San Group also is looking out for the best interests of local young people and the First Nations community in Canada.

The future continues to look very bright for San Group as the sky is the limit.

Learn more at www.sangroupinc.com.