“At RoyOMartin we have a saying, ‘We grow trees and people.’ We strive to be here for our employees in mind, body and spirit. This has allowed us to become the employer of choice here in Louisiana.” ~ Bobby Byrd, Executive Vice President of Strategic Planning and Research and Development, RoyOMartin

RoyOMartin, headquartered in Alexandria, LA, was founded in 1923 by Roy O. Martin Sr. After spending 11 years in the lumber industry between Indiana, Illinois and Tennessee, Martin Sr. wanted to go into business for himself. So, he and his wife, Mildred, purchased the Creston Sawmill in Alexandria, LA, for $32,000. The purchase included the plant, office and equipment, yet not a single acre. Today, after celebrating 100 years of Martin Sr.’s legacy, the company is now the single largest private landowner in Louisiana, owning 550,000 acres.

Throughout the last century and across 550,000 acres of land, RoyOMartin has grown substantially. The company currently has a solid wood and plywood mill in Chopin, LA, that produces 500+ million feet in structural wood panels, 35+ million feet of solid wood timber and three OSB mills in Oakdale, LA, and two in Corrigan, TX, that produce 2.2 billion feet. All of these facilities are APA certified.

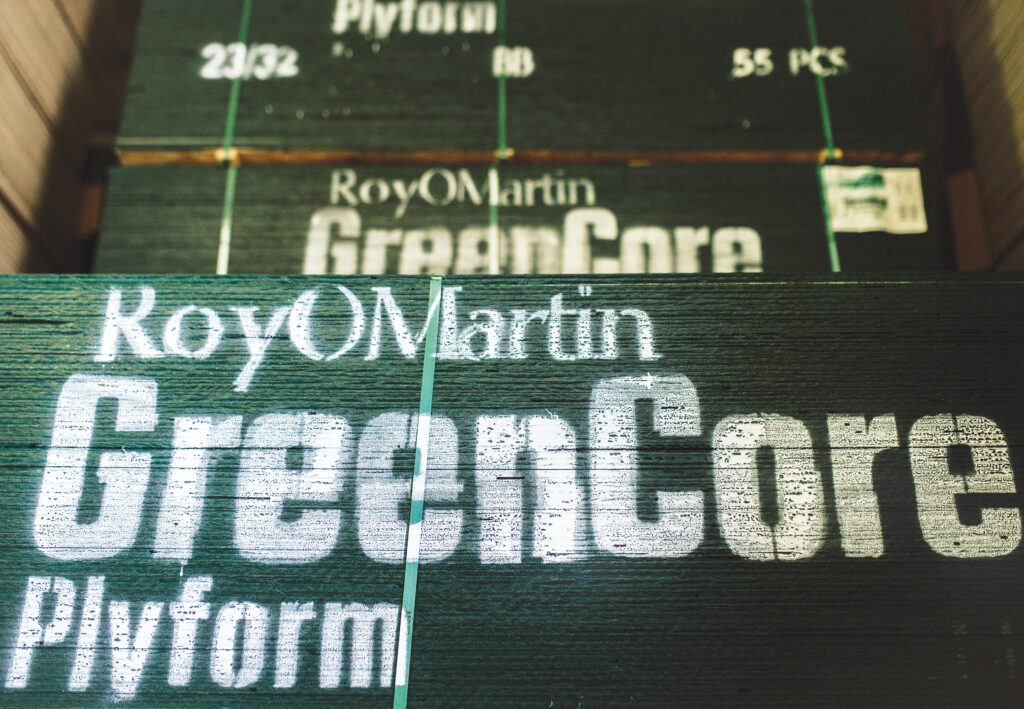

The Chopin plywood mill produces plywood in thicknesses of 1/4-inch, 11/32, 3/8, 1/2, 19/32, 5/8, 23/32 and up to 1-1/8 inch. “We have a diversified product offering that comes from our plywood mill that we sell globally,” said Bobby Byrd, executive vice president of strategic planning and research and development. “This is a high-grade mill, and we produce a lot of AC and BB type faces, in 4×8, fully sanded or rough panel. We also make our Plyform from this mill, which is edge sealed with a different color than the rest of the industry. We use a release agent on the face instead of oil, and contractors really like this product since it releases well from the concrete.

Chopin’s solid wood division produced 35+ million feet of timbers, sized in 4-inch x 4-inch, 5-inch x 5-inch and 6-inch x 6-inch, 8-feet and 10-feet lengths.

“We are always trying to continue to stay nimble so that we meet customer satisfaction and if we see that there is a demand for a certain product and it is within our capabilities to produce it, we will,” Byrd said.

The Oakdale mill can produce 800 million board feet annually, with its primary thicknesses being 7/16 and 15/32, in panels up to 9 and 10 feet long, as well as PET panels for the coastal areas of the Gulf of Mexico. “We produce what we call WindBrace, a PET panel that is 1-1/8 inch longer than normal so that the bottom plate can be tied all the way up to the top plate for high wind areas,” Byrd said. The WindBrace panels are produced in lengths of 9,10 and 12 feet and in thicknesses of 7/16 and 15/32.

The Oakdale mill also produces the Eclipse Radiant Barrier, which is Reflection Insulation Manufacturers Association (RIMA) certified. “We are one of a few companies that have the RIMA certification, and we have a unique member number that is printed on every panel that is produced at this mill,” Byrd said. Byrd went on to say that a true Radiant Barrier, according to the American Society for Testing Measurements, is less than 0.1 emissivity, as well as RIMA requiring that the barrier have Thermal Emittance, Adhesive Performance, Resiliency, Fungi Resistance, Water Vapor Transmission and Flame/Smoke Development.

The Corrigan mills have not only the capability to produce the value-added Eclipse Radiant Barrier, but a tongue and groove flooring line as well.

All four, Corrigan, Chopin and Oakdale, mills are positioned on the Union Pacific railroad and have the ability to load center beams, box cars, flatbeds and vans so that RoyOMartin has the capability to make sure that their customers are able to receive their products the fastest way possible.

“We are very sensitive to on-time deliveries, so while the end user may be separated from us, we are still ensuring that our customer, the distributor, can ensure that their customers get what they need on time,” Byrd continued.

The thought and care that RoyOMartin puts into the industry goes beyond caring for when their customers’ customer gets their orders. It is seen directly through the education programs that they offer for K-12 students, as well as, educating those already employed within the forest products industry.

“When I first started here, Jonathan Martin told me that he wanted me to go out and teach our customers the basics about our products. I thought that I would be done in a year. Yet here I am nearly 40 years later, and I am still teaching people in the industry the basics of OSB,” Byrd said.

Not only does RoyOMartin go to events that their customers are holding to give training sessions on how to properly install and handle structural wood panels as well as building tips for proper framing, but they also have a mentoring program for young high school students, Women In Manufacturing and Girls Can Too! These programs encourage women and girls to look beyond the traditional jobs that women have had, and to become more involved in the forest products industry.

Mentoring the next generation to come into the forest products industry is just the tip of the iceberg for how RoyOMartin looks out for and influences the community around them. With 1,300 employees RoyOMartin plays an integral role in their local economy from those that work in the mills, to those that work within in their medical facility and on their ministry staff. “At RoyOMartin we have a saying, ‘We grow trees and people.’ In order to grow people, we have to have all the benefits, so we have our medical facility, with doctors, nurses and pharmacists and we have our own ministry staff. We strive to be here for our employees in mind, body and spirit. This has allowed us to become the employer of choice here in Louisiana,” said Byrd.

RoyOMartin has not only positioned themselves to be a household name in their community, and to be widely known in the forest products industry as a company that produces and provides high-quality value-added services to their customers, but they have put themselves in a position to continuously be picked for special projects. Not only did they provided almost all of the material that went into the Wacker Street Tunnels in Chicago and the Ground Zero Project in New York, but they also sent rail cars of OSB to build the set of Titanic the movie. “There is a scene in the movie where Leonardo DiCaprio pulls up a park bench and you can see our Martco Mill # 220 grade stamp,” Byrd said, laughing. “So, when we asked for that clip, they told us not only could we not have the rights, but that they were also going to edit it out. Now you can only see the stamp on the original VHS, it has since been removed in all other copies.”

The Martin family has continued to lead the RoyOMartin company, with Roy Martin III currently serving as Chairman, CEO and CFO, and continuing to make all those that are employed by the company feel like family. Other senior officers include, Scott Poole, President and COO; Terry Secrest, executive vice president of manufacturing and sales; Jeremy Burford, vice president of plywood; and Lori Byrd, director of sales for plywood and solid wood division.

RoyOMartin is a member of the International Code Council, American Society of Testing Measurements, North American Wholesale Lumber Association, The Engineered Wood Association, Lumbermen’s Association of Texas, Mississippi Lumber Manufacturers Association, Texas Forestry Association and the Louisiana Forestry Association.

For more information, visit www.royomartin.com.