“We must be a low-cost, reliable producer to serve our customers best. Then, every decision of our capital expansion project has been geared to automation, technology, AI and people.”– Larry Huot, president and owner, DiPrizio Pine Sales

Depicted here is the McDonough high-speed optimizing edger equipped with a capacity for 30 million board feet of annual production.

Located in Middleton, NH, DiPrizio Pine Sales’ focus on “growing people” since their 1993 mill acquisition has resulted in decades of superior service with Eastern White Pine products. Recent capital investment heightens their commitment to excellence.

With a current annual production of 20 million board feet of Eastern White Pine, DiPrizio Pine Manufacturing & Sales is expanding production to 30 million board feet. LaValley Building Supply is a Northeastern, independent, family owned and operated company with 13 lumberyards and home centers in New Hampshire and Vermont.

LaValley is committed to manufacturing and has been building trusses and wall panels longer than anyone in New England according to DiPrizio Pine Sales president and principal owner of LaValley Building Supply, Larry Hout. Their modular homes division, Preferred Building Systems located in Claremont, NH, ships energy efficient homes to the New England region. Modular homes and off-site construction bring new home building to a whole new level of solutions for builders and homeowners.

“Striving since 1962 to innovate and invest in equipment, people and processes, the company is committed to deliver more savings for your dollar. This process brings trusted services and lasting relationships for all,” said Huot.

This image depicts Comact’s artificial intelligence “grade expert,” which is, according to DiPrizio, the “most renowned grading system in the industry.”

DiPrizio Pine Manufacturing & Sales ships about 50 percent of their products to wholesalers and wholesale distributors. As a member of the Northeastern Lumber Manufacturer’s Association and the North American Wholesale Lumber Association, DiPrizio specializes in reliable quality, on-time/in full delivery of 4/4, 5/4, 6/4 Common and proprietary grades including a breadth of patterns and textures to serve end users in manufacturing and retail industries. The company values operating with a “standard that will reliably provide the best services, experience and lowest overall costs for customers,” noted a company representative. Huot said, “We must put ourselves in our customers’ shoes, consistently supplying products and convenience while insightfully removing costs for them. This approach drives engagement with our people at every level where voices are heard. Leadership is grown in decisions that serve personal development and opportunities company wide. We always strive to improve quality and efficiency geared toward systems handling and are devoted to highly technical automation.”

Depicted here is a Nicholson “A-6” debarker that is, according a DiPrizio company representative, “widely considered the best in the industry.”

DiPrizio’s clients directly and indirectly include architects, designers, custom craftsmen, home builders and retail customers. “Through our retail contractor home centers, we serve these markets directly. We are close to our customers in understanding their needs which is a competitive advantage that serves all our clients and their customers the best,” added Huot.

As for the future, Huot explained their vision for the company is to be “heavily committed to major investments in controls, scanners, technologies and people. Life-long students are attracted and retained by these inspiring commitments. Rising stars in the industry are the life-long students who will grow their careers in our fabulous industry.”

“Our staff is unbelievable in their desire to learn and embrace all the new equipment and processes. Our ‘team of teams’ has an uncommon thirst to understand our purpose and long-term benefits by applying qualities and terminology such as ‘best decisions’ and ‘job ownership.’ These skills are adopted by our talented people to overcome what many may think is impossible, creating confidence and success.

Shown here is the 90-degree delivery from the automatic trimmer to the 32 bin automatic width and grade sorter.

Our aim at DiPrizio Pine Manufacturing & Sales is to deliver compelling reasons with reliability, trust and consistency for our customers, employees and suppliers, driving their desire to do business with us. Our belief in our exciting industry is that ‘we can always do better’ to serve our communities with our experienced and innovative employees, coupled with the unequaled characteristics of Eastern White Pine,” noted a company representative.

Jamie Moulton, sales manager at DiPrizio, who has been in the lumber industry for many years, noted the importance of details and communication with customers and employees. Moulton also stated that Jeff Winslow, their general manager “has been unbelievable,” because of his work ethic and his knowledge of the industry. Huot builds on Moulton’s praise for Winslow by adding that he has the “people knowledge to have the perseverance to grow people” and the ability to provide clarity of understanding and purpose.

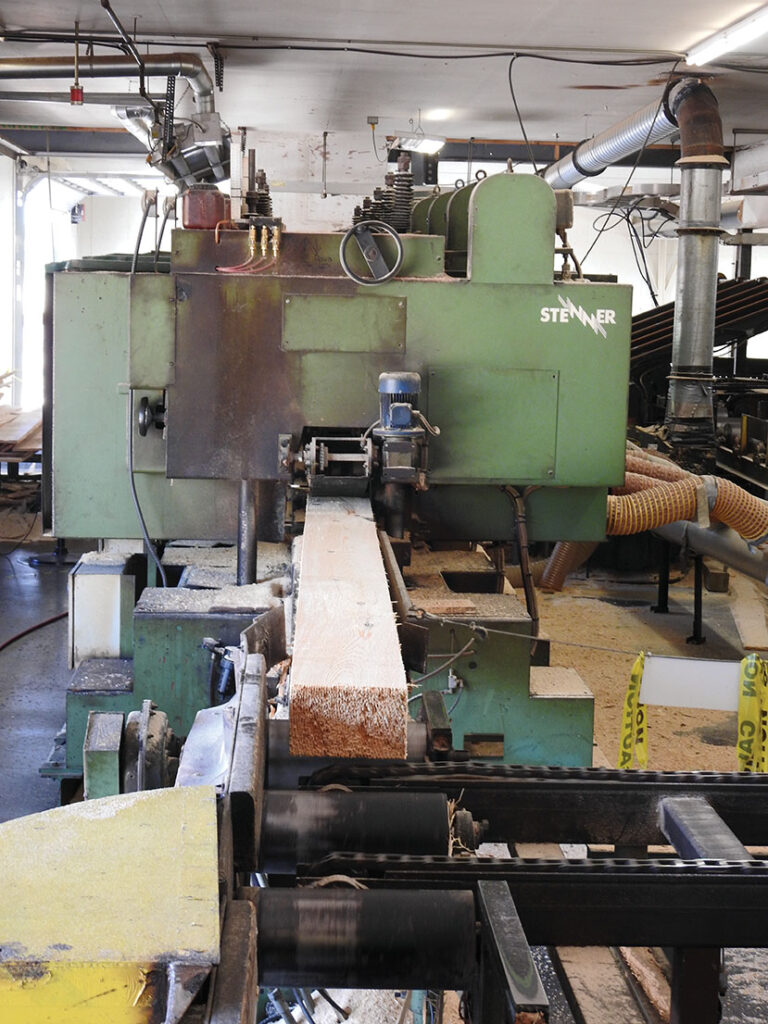

This image depicts DiPrizio’s 5-head, thin-kerf, horizontal machine center Stenner band.

A company source stated their manufacturing facilities are “fully stocked with highly optimized controls, equipment and technology. This assures our customers in everything from log scaling to log break down we are manufacturing reliable and consistent end products.”

Huot stated that they transitioned from a RosserHead debarker to a Nicholson A6. DiPrizio has a Cleereman double cut and an A10 circle saw, which will be switched out with a secondary breakdown or a secondary double cut to preserve fiber at a later date.

DiPrizio also decided on the highly technical McDonough Manufacturing Company optimizing edger. The waste flow system was changed as well, now run by belted travel and augers. It is “much cleaner from a byproducts standpoint, has a lower operating cost and keeps heat in the mill,” Huot said.

In addition, they have the Weinig and the Hydromat 23, which is a six-knife, six-head machine that operates at 6,000 RPMs in addition to their Yates-American planer. “A very big part of our sawmill expansion investment has been the AI ‘trim expert’ grading system by Comact. This technology captures the most fiber possible, reducing waste and low value byproducts. The automatic grading has improved the consistency of grade from the sawmill, serving the planer mill much better,” noted Huot.

A TS Manufacturing automated stacking system equipped with automated lift skids for box piling with an accuplacer for eight-foot precision stick alignment is shown here.

The 40-acre manufacturing site generates their own energy, has three power plants and an oil-fired Hurst Boiler & Welding Co, Inc. boiler as a back-up. Their biomass Hurst boiler is aligned with a 600KDW turbine as their primary energy source and a 1-meg solar power plant. Huot also mentioned a major investment decision in the TS Manufacturing automatic stacker, which has proven to be successful.

Huot explained that the LaValley Building Supply companies and DiPrizio Pine Manufacturing & Sales have historically aspired to be the most innovative in meeting customer needs to excel at serving their customers in the most meaningful ways.

Visit www.dipriziopine.com to learn more.