MiCROTEC, located in Corvallis, OR, continues to flourish and grow as innovators of artificial vision in the forest products industry. Founded in 1980, MiCROTEC expanded their ever-growing umbrella of companies through their acquisition of Lucidyne Technologies in 2020. After a complete brand integration in 2022, MiCROTEC continues to strengthen their foothold in the North American and international wood processing industry.

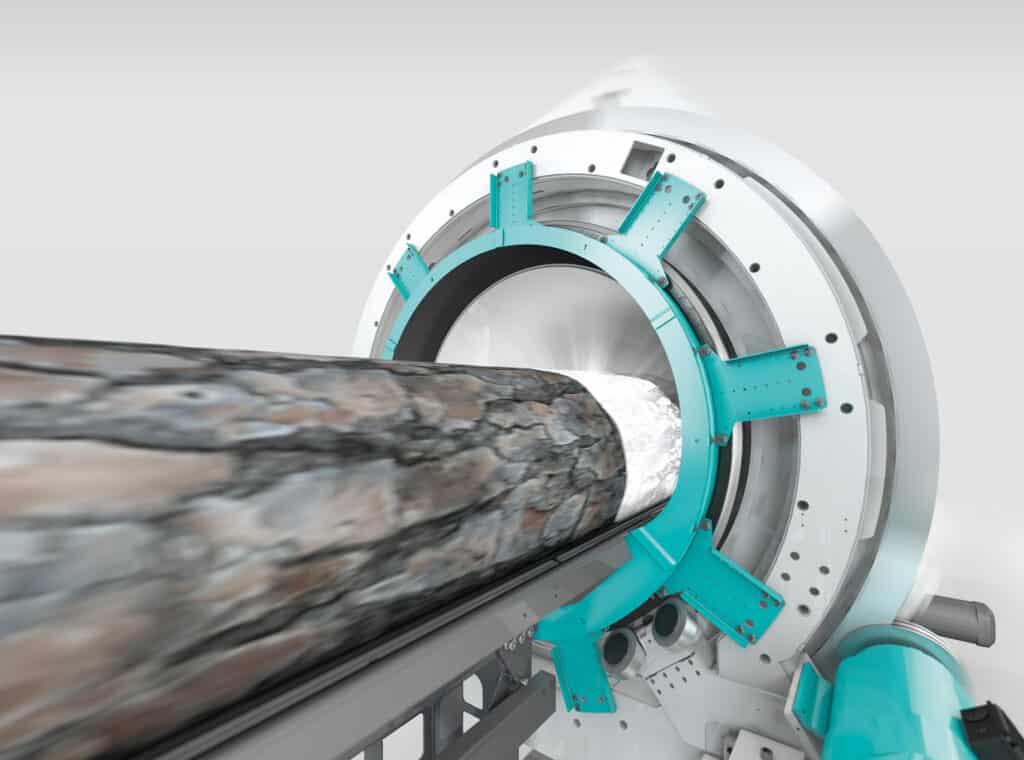

MiCROTEC ramped up technology developed in the 1990s, moving from a focus in softwood to investing more in Hardwood. With a start in X-ray scanning, they moved to address the Hardwood lumber industry’s needs by innovating technology to scan higher density lumber. This led to the development of their flagship product, the CT Log Scanner. The CT Log is a sawyer’s dream. It is the only technology available to see all defects inside the log. The CT can identify everything including rot, shake, knots, stain, metal, heart/sapwood. With the use of our state-of-the-art integrated software platform, MiCROTEC can identify the best degree to open the log and determine how each board should be sawn. The system will identify which thicknesses to be cut and what grade each board will be.

“This technology gives a much higher yield and recovery improvement. The Hardwood industry is benefiting greatly from this technology. It improves the yields because the quality and value of the logs is greater,” said Chief Sales Officer of the MiCROTEC Group, Arianna Giudiceandrea. “A CT scan can in general uplift the value independently based on what type of log you pass through,” she continued. The customer can then scan the log before it is even cut, allowing for the detection of internal features before it has been run through the mill, predicting exactly where to cut to maximize its value and recovery.

With the wide range of classifications used for Hardwood grades and species, the MiCROTEC family dedicated a branch of the company to develop the Woodeye Hardwood Grader, a lineal board scanner, which helps their customers streamline this process. Woodeye identifies knots, cracks, splits, shake, and other defects in accordance to NHLA rules or any proprietary grades the mill has. “While fulfilling the expectations of NHLA was not easy, we wanted to be able to continue to make the software customizable for individual customers,” said Frank Jöst, CEO of MiCROTEC.

Stefan Nilsson, CEO of MiCROTEC’s subsidiary Linkoping and the competence center within the group for Hardwood, also stated, “There are many Hardwood species, and each has their own challenge. This has been a long process, maybe over 30 years, to get to where we are able to have specific settings for each species.”

MiCROTEC’s approach is to have a large product portfolio for their customers to allow for integrated solutions. For example, on the carriage side there is new technology that, as Giudiceandrea said, “has revolutionized the industry because it is based on stereoscopic imaging. This gives the customer an accurate measurement of the log while it is rolling onto the carriage without any occlusions or shadows and allows them to optimize the cuts of the log while it is still rolling on to the carriage.” MiCROTEC’s unique log stereoscoping imaging system, Logeye Stereo, is the only patented scanner worldwide that provides full 360-degree scan as the log rolls onto the carriage.

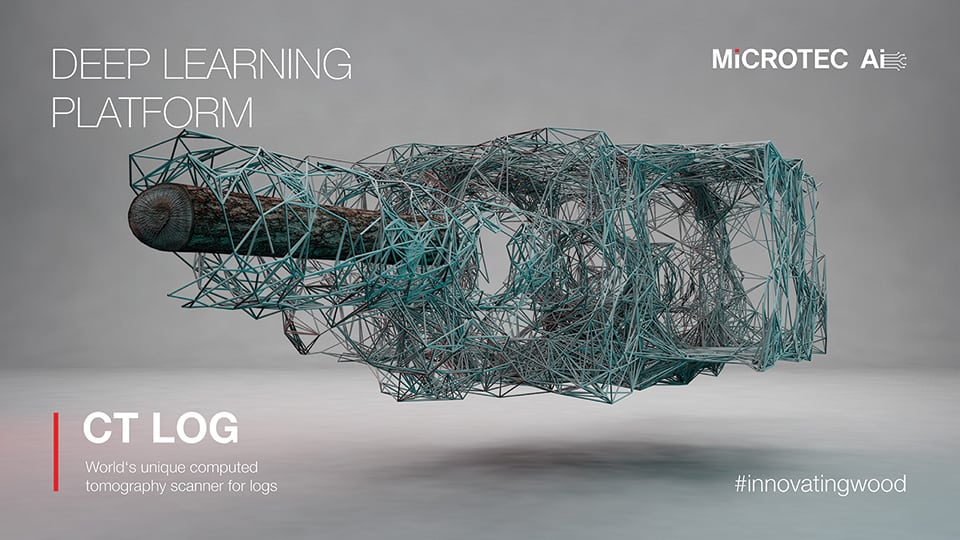

In 2019, MiCROTEC introduced the Digital Fingerprint Concept and rolled out deep learning AI into all their quality scanning systems. “AI has become a critical factor in finding a lot of different unique aspects of each species. We have a very strong team dedicated to AI that continues to show the ample experience that we have when it comes to deep learning, and how it will also help the Hardwood industry just as it helped the softwood industry when we initially brought AI to them,” Jöst said.

Giudiceandrea continued by explaining that the more examples of defects the MiCROTEC Ai platform is fed, the more it will learn. “One of the challenges in the AI market is the tool set. There aren’t a lot of tool sets on the market. We had to develop a lot of these tools sets to be able to manage the millions of board images that we have. That’s what sets us apart, we have developed these tools that aren’t just readily available to buy off the shelf. We’ve spent a lot of time customizing them and we are making them work for you,” Giudiceandrea stated.

MiCROTEC prioritizes continued support to keep customer operations up to date. With ever evolving technology, MiCROTEC provides the support to keep the software and hardware updated. “We want to support our customers for a lifetime” Jöst said. This back-and-forth dialogue between MiCROTEC and their customers allows its customers to build a relationship with the company through the MiCROTEC Connect platform and the Grading Support Team. MiCROTEC offers 24/7 support to answer the ongoing needs of their customers.

MiCROTEC offers a wide range including but not limited to: CT Log, Logeye, Logeye Stereo, Goldeneye, Lucidyne, and Woodeye.

MiCROTEC is a member of Southeastern Lumber Manufacturers Association, Southern Forest Products Association, Indiana Hardwood Lumbermen’s Association, National Hardwood Lumber Association and Mississippi Lumber Manufacturers Association.

To learn more, visit their website at www.microtec.us.