By Scott Dalton

Dundee, OH—You could be forgiven if you are not yet familiar with Crafted Elements, located here. They are, after all, relatively new to the industry. But the craftsmanship that goes into their work reveals that, while the company may be new, there is a lot of experience behind the name.

“My career began in 1992 at the age of 16 at my father’s metalworking job shop as a custodian and general laborer,” craftsman and owner Todd Dennison recalled. “At the age of 17, I began to apprentice under some of the journeyman machinists at the company, including my father. I spent the next several years not realizing that I was learning and practicing valuable machinist skills that I would later-on use to build my career in woodworking.”

Dennison was later offered a floor-level machine set-up/operator position in a custom woodworking shop, and worked his way up to the plant manager position over the next few years. By 2006, he and two partners had purchased the company.

“We then purchased two stair component manufacturing companies in 2007 and 2008 and combined the three companies in one location in Newcomerstown, OH,” he said. “In 2009, I sold my ownership in those companies and worked with Brown Wood Inc. to open up a manufacturing facility for them. I managed that facility for nine years before ultimately purchasing the manufacturing facility from them and starting Crafted Elements. Our focus is on manufacturing high-end custom wood, metal, and acrylic components for many industries.”

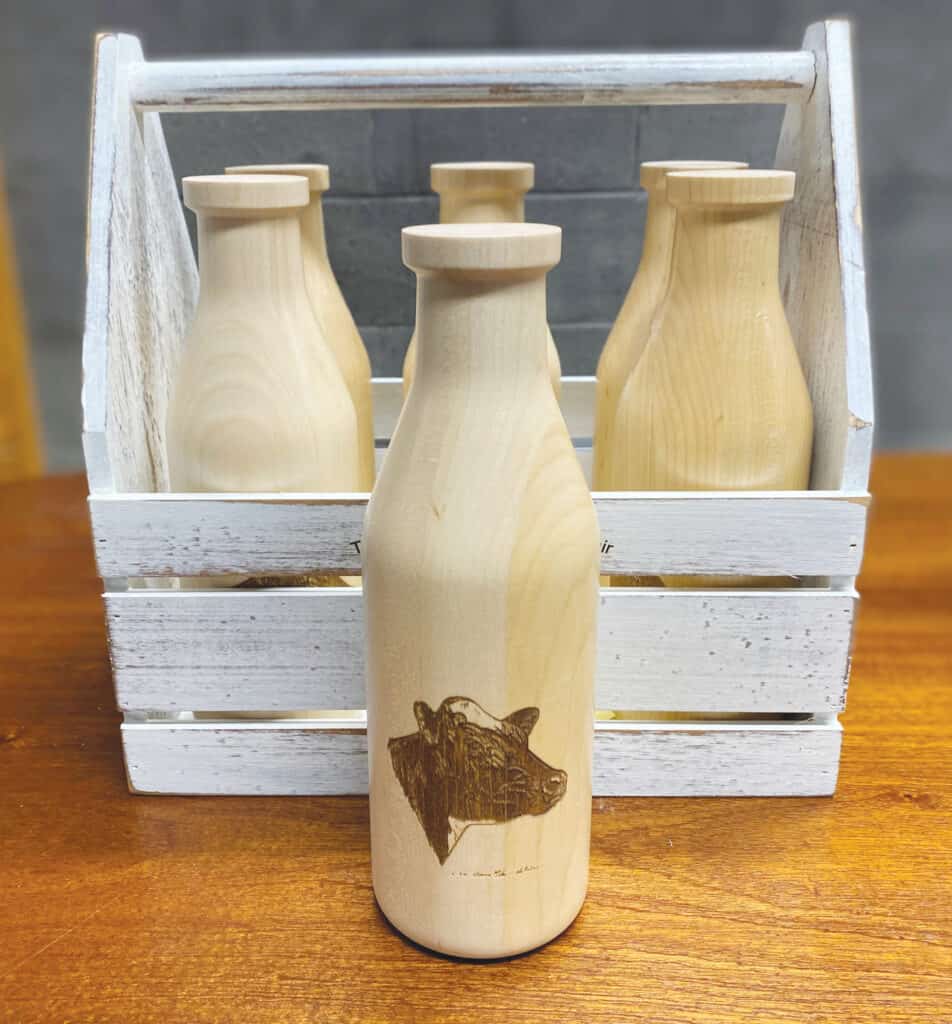

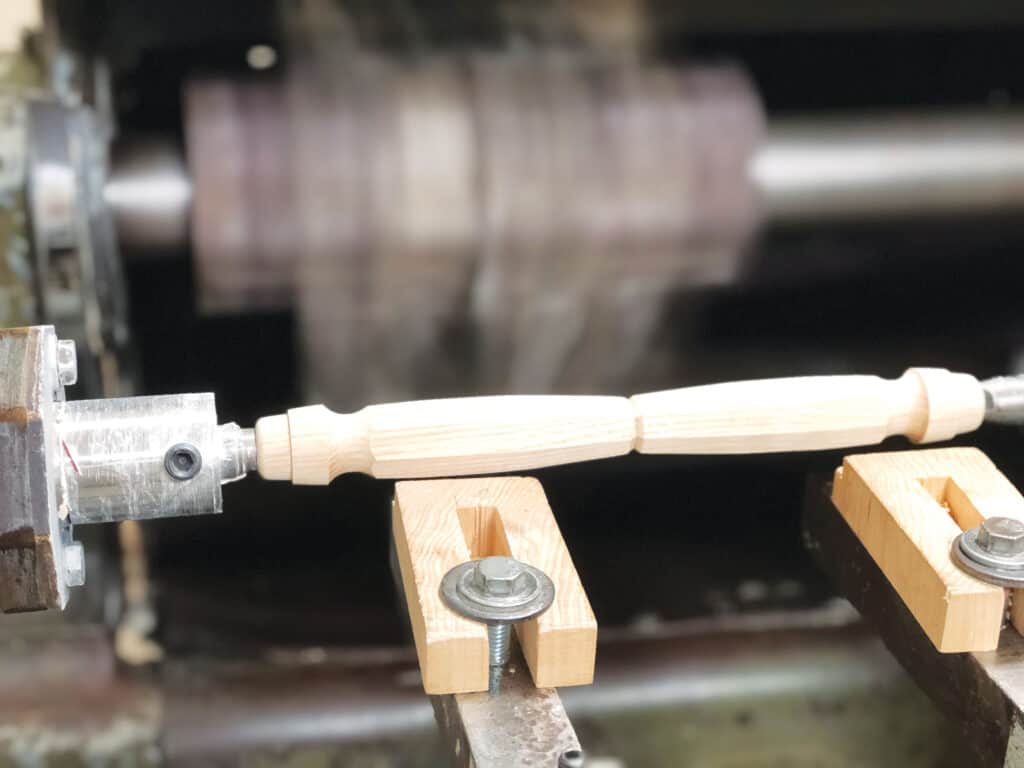

Crafted Elements is a manufacturer of mouldings, carvings, large diameter turnings, decorative legs and bun feet. Annual lumber purchases total approximately 300,000 board feet of Hard and Soft Maple, Red and White Oak, Poplar and Cherry, as well as Alder, Walnut, Birch and Beech (No. 1 and No. 2 Common, Select, 4/4 to 16/4, S4S, 6 to 8 percent moisture content). Most of their material purchases are in the form of laminated turning blanks that are S4S, and PET. Crafted Elements works with a long list of wood species, because the company takes pride in its versatility. “Our willingness to work with any species is one of our big advantages,” Dennison said.

“One of our core beliefs is that above all else, we should have a positive impact on those we work with and serve. Many of our employees take this to heart and strive to make this approach a part of their everyday lives.”

Todd Dennison, a craftsman for and the owner of Crafted Elements

The company also works with a variety of customers, including fellow craftspeople, such as architects, furniture makers, designers, and cabinet makers. But the Crafted Elements crew has also provided high-end work for the restaurant and hospitality industries, as well as individuals. Essentially, no job is too big or too small for them to handle.

“We really do serve a wide range of customer types. Our largest segment is kitchen and bath, as we have a knack for very high-end, large diameter column turnings,” Dennison said. “That being said, we have seen a great deal of growth in OEM-type work because of our versatility in manufacturing. We frequently get asked to produce very unique products from all segments. It’s one of the things that we love about what we do – every day is a new adventure for us.”

The company features a leadership team that includes Master Craftsman Ed Dennison, Procurement/Inventory Manager Val Raderchak, and Shipping Manager Julie Springer. Todd Dennison said that the other key members of the Crafted Elements team come from many walks of life, including people from the printing, woodworking, masonry and construction industries.

“Three of our most important production team members came in with very little woodworking experience, but have become exceptional craftsmen, helping to establish the success that we have had to this point,” he said, adding that employees at the company are a close-knit group. “One of our core beliefs is that above all else, we should have a positive impact on those we work with and serve. Many of our employees take this to heart and strive to make this approach a part of their everyday lives.

“Most of our employees meet together every day at 9:45 voluntarily to read from devotionals and discuss topics that they feel will steer them toward being better people and us a better company. It’s really incredible to see them do this.”

The team worked in a 12,000-square-foot facility, as well as a 25,000-square-foot warehouse. However, in 2020, “We ended up moving to a larger location in order to expand our capabilities,” Dennison said.

The team utilizes a variety of equipment, including Mattison Rotary Lathes, Wema Copy Lathes, Hapfo, and CNC Copy Lathes, using them to craft magical creations, including everything from one-of-a-kind custom-designed tables and desks to specialized toys and award plaques to architectural columns up to nearly two-feet in diameter.

Although the company is relatively new, Dennison has already set his sights on where Crafted Elements can grow next. “We do have hopes of expanding,” Dennison said in early 2020. “We have expanded our capabilities via new CNC equipment and additional craftsman-level employees to help us reach our goals.” One year later, he stated, “We have been blessed with tremendous growth in what proved to be a very difficult-to-navigate year. We currently have 26 employees up from eight employees in January 2019. We have expanded our capabilities and our output capacity in preparation for what we hope will be a fantastic year in 2021.”

Bringing things full circle, Dennison today once again works alongside his father, who joined him in woodworking in 2005. “His now-47-years of machinist skills and management are invaluable to our success at Crafted Elements,” Dennison said of his dad. “He uses his years of experience to take our staff under his wings and develop them into effective craftsmen for our company.”

Even with all this talent and dedication to the craft, Dennison said that what sets Crafted Elements apart are the relationships that it helps build. “We think the most interesting thing about our company is our focus on people rather than just profit,” he said, adding that the Crafted Elements team works together to live the company’s mission. “We truly strive to impact our employees, vendors, customers, and our community in a positive manner with every interaction that we have with them through our passion for woodworking and craftsmanship.”

For more information, go to www.craftedelements.business.