50 Years of Quality

In a world of continual change, there are few constants that businesses can rely on. Lewis Controls Inc., based in Cornelius, OR, is one such constant in the lumber industry, having trailblazed innovative technology and steadfast quality for over 50 years. The company’s enduring success is driven by a continuous forward-thinking approach and a commitment to upholding high standards of startup quality and service response.

Full ReadyScan III System with operator display and console/handles.

Lewis Controls was established by industry pioneers Dick Girouard and Bob Lewis, both were pioneers in the development of hydraulic linear positioners and optimization technology. Today, in partnership with Corley Manufacturing of Chattanooga, TN, the company specializes in primary breakdown systems for sawmills and selective downstream machinery.

Reflecting on the company’s origins, CEO Chip Corley said, “Dick Girouard and Bob Lewis were electronic innovators, doing any electronic control application they could find in the Pacific Northwest. Over time, they transitioned into creating setworks for carriages and edgers. As the industry has evolved over the past half-century, Lewis Controls has remained a dependable and constant presence.”

In the intervening years Lewis continued their focus on large log processing, mostly as a complement to Corley’s product line but also as an independent force in scanning and setworks technologies for the headrig.

In 2001 the innovative side of Lewis resurfaced when they introduced their highly successful “Readyscan Carriage Scanning and Setworks with 3D scanning. The unique draw of the Readyscan was that it was the first 3D system that was simple, practical and relatively affordable. It was an instant success and over 100 of these units were soon operating worldwide.

ReadyScan III console with full color HMI screen.

The first major upgrade to the product line came seven years later with the newly designed Readyscan II which soon became the most popular and duplicated carriage scanning system ever installed. Featuring a streamlined and more robust hardware design, over 200 units were produced.

An Eye On The Future

Not content to stand still, Lewis has quietly introduced the next generation, the Readyscan III. Departing from the long held Lewis philosophy of controlling their headrig systems through their optimizer computer and proprietary interface, Readyscan III uses a main PLC combined with the industry Standard “Delta RMC” for machine and setworks control and a high speed, mill ruggedized PC for scan, setworks and report functions. The new design still retains all of the advanced optimization features that were popular among earlier Readyscan releases and many more.

On the Optimizer side to name a few, a newly designed operator display with better graphics is the most visible change. On the less visible side true multiple cant options are available in addition to the standard Cant Matrix and Dollar Driven modes. Easily adjustable opening face software makes dialing in faces simple. On new installations customers have the choice between LMI Chromascan sensors and JoeScan sensors. For existing Readyscan II customers, the Readyscan III system can be installed in their existing cabinets using the LMI Chromascan scanner currently in place at a significantly lower price than a full replacement.

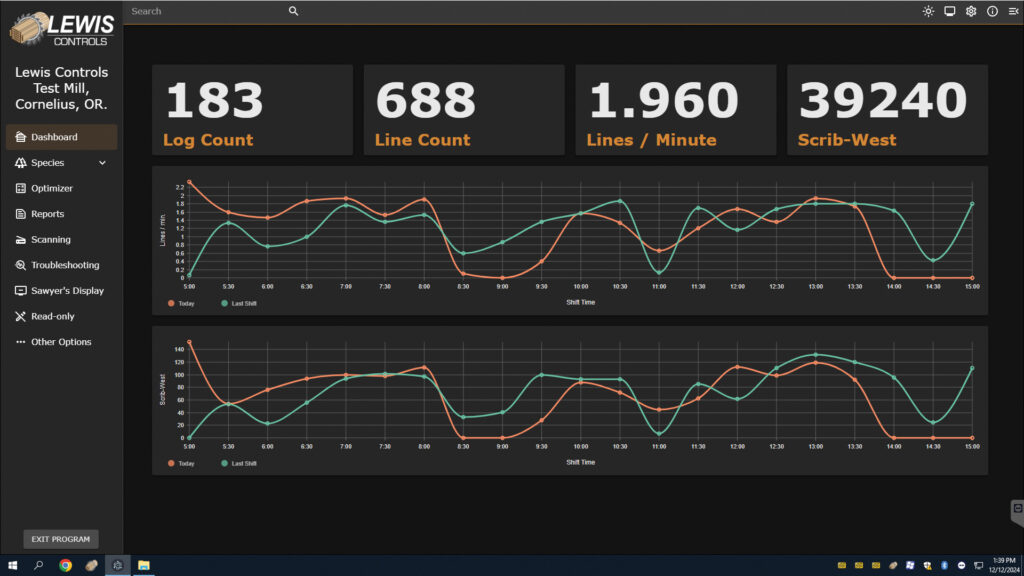

ReadyScan III dashboard production tracking screen.

ReadyScan III operator display.

Lewis Controls building in Cornelius, OR.

However, the PLC side is where the true innovation begins. Dynamic carriage configuration and programmable routing allow a mill to “future proof” their system. If you choose to change your carriage design, outfeed, infeed, slab drop, or routing to downstream machines the system can be adapted in a matter of moments over the dedicated service line. All displays linked to the PLC can be field customized to suit mill preferences. If you want more information, it’s there. If you want less information for a simpler look, that’s available as well. Troubleshooting tools for software and lighted fuse connections are only a few of the key improvements you’ll notice.

As always, Lewis Controls also offers a full set of spare parts on deferred billing terms post-installation and provides complimentary technical phone support. The company’s core values of responsibility and commitment to customer service set them apart in the industry.

ReadyScan III operator console HMI display.

With Chuck Boaz from Corley leading sales effort and overseeing operations, the company focus has not changed since the early days. “We have been known for quality, service commitment and innovation. We have no plans to change that.”

For more information, contact Chuck Boaz, Corley Mfg. (423) 698-0284, Chris Hough, Lewis Direct Sales (503) 648-9119, or your local Corley representative. You can also visit www.lewiscontrols.com.