By Scott Dalton

“We are constantly looking for new products and new services to support our customers. Over the years we have added priming, finishing, and sanding services to meet their needs. We recently added engineered flooring using our own wood.” – Ed Godek, III, director of marketing, Rex Lumber Company

The Rex Lumber Company story could be told using a few basic, but important, numbers.

- Three – the number of generations that the Forester family has been operating the company.

- Sixty-plus – the number of species of lumber that the company offers.

- Sixty-thousand-plus – the number of custom moulding profiles available.

- Twenty-million-plus – the number of board feet of lumber the company purchases in a year.

Although impressive, these numbers only begin to scratch the surface of what makes Rex Lumber such a unique and successful company, according to Director of Marketing Ed Godek, III. Godek has been with Rex for more than 28 years, and yet remains one of the more recent additions to the company.

“We have approximately 15 road salespeople and about 13 inside salespeople, and there are only a handful of people with less longevity than I have,” he said. “Our sales manager has 30-plus years here. We are known for being a place, especially on the sales and management side, that enjoys longevity.”

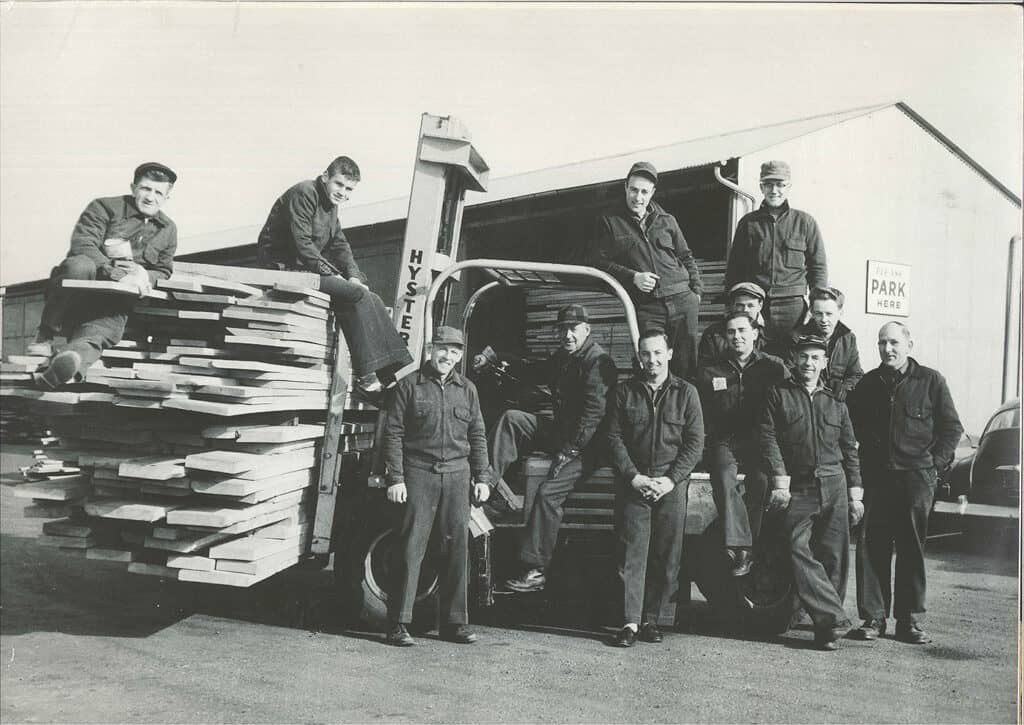

That commitment and sense of loyalty on the part of the staff of Rex Lumber has helped ensure its growth for more than 75 years. The company got its start in 1946 when Paul Forester Jr. opened his first facility in Somerville, MA. Paul followed up on his early success, opening a second location in South Windsor, CT in 1951 and introducing custom milling options for his customers. By 1971, the company had added a new operation in Englishtown, NJ, which also featured kilns. In 1980, Rex moved its headquarters to its current home in Acton, MA. Six years later, the company expanded once again, this time in Doswell, VA.

All of Rex’s locations have millwork facilities including moulders, with kilns located in both New Jersey and Massachusetts. Not surprisingly, with such prodigious processing ability, the company needs a steady stream of lumber to meet its customers’ needs.

“We purchase about 20 million board feet a year,” Godek noted. “About 75 percent to 80 percent of our material has millwork applied to it. It could be blanking, or blanking and ripping, or a moulding that is sanded with a stain, sealer, and a conversion varnish sprayed on it that is ready to install, and everything in between.”

Godek pointed out that one of the things that distinguishes Rex from its competitors is the fact that it was one of the first to be certified by the Forest Stewardship Council®, as well as one of the earliest to provide millwork services. At the same time, the company works diligently to make sure it is not competing with its customers in terms of what they offer.

“We look at the services our customers need, and for many of them, we become an extension of their own mills. For some we run their bigger runs of stock and custom mouldings, so that their mills can focus on their custom millwork and short moulding runs. This prevents their mills from being bogged down doing work that is easier for our facilities to do, thus allowing them to focus on higher-value shorter runs internally,” he said. “Besides our relationship with our employees, we want to make sure we have a good relationship with our vendors and customers, many of whom have been with us 30, 40, or even 50-plus years.”

As part of this, Rex Lumber is always listening to its customers in terms of their needs. While building and renovation remains at the core of its sales, everyone from amusement park owners to flooring retail operations to musical instrument builders and casket makers have turned to the company to meet their unique lumber needs.

“The musical instrument makers prefer our South American Mahogany and Hard Maple supplies. We sell to both piano and guitar companies,” Godek noted. “What has also been good for us has been government agencies, especially for what goes on their older, protected structures. We supply Accoya®, which is an acetylated hardwood.”

He explained that Accoya® is produced using a proprietary pressure treatment process with a high-tech vinegar. This modifies the wood to the core at molecular level, but unlike other pressure-treated lumber, produces nothing but 100 percent natural byproducts that could be made into consumer-grade vinegar.

“It’s exceptionally dimensionally stable and decay and rot resistant. This makes it great for windows, doors and restoration work. The National Park Service has approved it and uses it for their renovations; it has been used in multiple projects in both New York, Massachusetts, and elsewhere,” Godek said. “When regular wood gets wet, it swells and shrinks, which is the primary reason coatings fail. The fact that Accoya® is much more stable means that coatings and paint last substantially longer. How many woods out there have a 50-year warranty against decay and rot?”

Such unique products have allowed Rex Lumber to diversify its customer base in a way that is the envy of many of its competitors. Godek pointed out that even during the 2007/2008 housing crisis, when the entire economy seemed on the verge of collapse, the company has been able to weather the extremes of the market with relative ease.

“Even during COVID, we never shut down,” Godek said. “The industry was considered essential. So one, we could keep people employed and at work, and two, we had some of the biggest backlogs in our history. People were looking to renovate their homes when they could not go anywhere.”

Although high demand became problematic for many lumber companies when they could not keep pace with customers’ needs, Rex Lumber was better positioned, thanks to an equally diverse range of suppliers.

“We never ran out. White Oak became a challenge for everyone on the planet, but we were able to keep enough material coming in and keep everything running,” he said, adding that some of the lingering issues associated with the pandemic continue to affect the industry as a whole. “White Oak is still a challenge, and that is an industry-wide thing. With the current supply of White Oak coming in, we are seeing more and more defects being allowed, and customers want fewer and fewer defects, so that’s a challenge.”

When it comes to interest in specific hardwood species, most are relatively easy for Rex Lumber to source. The company is a direct importer of South American Mahogany and gets a number of species directly from Africa. Godek noted that Poplar remains extremely popular, as do most of the domestic species, including Red Oak, White Oak, and Maple. He reiterated that Accoya® has been a strong seller, as have other products produced by Accsys Technologies, including Tricoya®, an exterior MDF, and a new line called Accoya Color®, which features a gray dye impregnated into it.

With so much going for it, it’s no surprise that Rex continues to look for opportunities to expand.

“We are very strong from Maine to North Carolina. We go down to Florida and South Carolina on a regular basis with our own trucks. We are looking to grow a little more to the west and strengthen further south,” Godek said. “We are constantly looking for new products and new services to support our customers. Over the years we have added priming, finishing, and sanding services to meet their needs. We recently added engineered flooring using our own wood. We continue to look to our customers’ needs, as well as continuing to strengthen within our own markets.”

For more information, visit www.rexlumber.com.