AHC Hardwood Group Expands Sales Team

Jason Pancheau

AHC Hardwood Group, located in Atlanta, GA, announced the expansion of their sales team with the addition of three experienced professionals: Jason Pancheau, Chris White and Sue VanEss.

Pancheau brings a rich background in high-end furniture craftsmanship. With more than eight years in the hardwood industry, he comes to AHC Hardwood Group most recently from Northwest Hardwoods. His sales territory includes states in the Mountain and Pacific time zones.

Along with other value-added products, as territory account manager, Pancheau will help to expand Lunawood Thermowood® products into the territories of Idaho, Montana, Wyoming and Northern California. A native of Billings, MT, he attributes his strong work ethic and appreciation for nature to his upbringing. In his leisure time, Pancheau enjoys woodworking and outdoor activities.

Chris White

White began his journey in the lumber sector with 84 Lumber, later transitioning to the hardwood industry. With more than 25 years in the lumber and hardwoods industry, he comes to AHC Hardwood Group most recently from Choice Hardwoods.

In addition to selling value-added products produced at the AHC Clarksville, TN, facility, White will serve as the territory account manager for the areas of western Tennessee, northern Mississippi, northern Alabama and Arkansas during the AHC expansion of Lunawood sales. White has lived in various locations, including Tennessee, North Carolina and Texas. He now calls Birmingham, AL, his home base.

Sue VanEss

VanEss began her career with Stiles Machinery in Grand Rapids, MI, gaining insights into woodworking and machinery’s role in production. She further expanded her expertise with Weyerhaeuser/Northwest Hardwoods, delving into sawmill operations and hardwood lumber production. VanEss brings more than 18 years of experience to AHC Hardwood Group and will serve as the territory account manager for Minnesota, Wisconsin, North and South Dakota, Nebraska and Kansas. Residing in Grand Rapids, she enjoys home renovation projects and spending quality time with her family, including her two children and six grandchildren.

The expansion of the AHC Hardwood Group sales team is part of a nationwide expansion as Atlanta Hardwood Corporation gears up for the introduction of Lunawood ThermoWood® hardwood products. Lunawood production is scheduled to begin with locally sourced hardwoods mid-summer 2025 in a new facility in Cleveland, GA.

For more information, visit hardwoodweb.com.

Ron Jones Harwood Sales Inc. Welcomes Isaac Jones

Isaac Jones

Ron Jones Hardwood Sales Inc., located in Union City, PA, recently welcomed Isaac Jones to their team. Jones will be involved in sales, purchasing and network administration.

Ron Jones Hardwood specializes in the manufacturing and sales of premium Northern Appalachian Hardwood lumber. They offer thicknesses ranging from 3/4 – 8/4 and species include Cherry, Red Oak, Hard and Soft Maple, Poplar, Hickory, Ash and Yellow Birch, in rough or surfaced.

Jones started working for the company during high school, where he would work on the lumber yard at the company’s Franklin, PA, location during the summer, he did this throughout college. During this time, he gained experience operating the stacker, laying stickers and tallying lumber with the Vision Tally System.

Before joining the Ron Jones Hardwood team fulltime, Jones worked in the logistics industry where he worked for Logistics Plus, handling contracts for companies such as Google and Wabtec.

“I am excited to join the industry as a third-generation lumberman. This opportunity allows me to continue my family’s legacy while embarking on my own journey. Although I have much to learn, I am eager to absorb knowledge from experienced colleagues and contribute to the industry’s growth. I look forward to embracing the challenges ahead!” said Jones.

Jones graduated from Union City High School in 2018 and earned a degree in Project and Supply Chain Management from The Pennsylvania State University, University Park, PA, in 2021. During his time in college, he was a sprinter for the track and field team at Penn State Behrend, Erie, PA.

In his free time, he enjoys reading, listening to music, hiking and enjoying the company of his dog and two cats.

For more information, call 814-438-7622 or visit ronjoneshardwood.com.

Boise Cascade – Building Materials Distribution Promotes Joanna Barney To Executive Vice President And Nathan Sikes To Senior Vice President Of Western Operations

Joanna Barney

Boise Cascade Company, based in Boise, ID, recently announced that Joanna Barney will be the new executive vice president of their Building Materials Distribution (BMD) division. And that Nathan Sikes will be the senior vice president of Western Operations for their BMD division.

Barney will oversee the company’s 40+ distribution facilities, including millwork and door shops, across the U.S.

Barney joined Boise Cascade in 2005. Prior to this promotion, she was the senior vice president of BMD Western Operations. Before that she served in several key roles and progressive leadership positions, including general manager of BMD Western Operations and branch manager for BMD’s Salt Lake City, UT, location. Barney earned a bachelor’s degree in business finance from the University of Utah. She is a two-time all-American athlete and the founder and executive director of the Utah Avalanche youth soccer club.

Nathan Sikes

Jo is an accomplished and inspirational leader who is committed to our company’s values,” said Jeff Strom, COO. “I’m excited to see the positive impact of her leadership, experience and ideas in this new role.”

Nate Jorgensen, CEO, said, “Jo has achieved significant accomplishments during her time at Boise Cascade, and she will be outstanding in this new role. She has a proven track record of living our values, providing strong leadership and delivering exceptional service to our customers and suppliers.”

Sikes will be responsible for BMD’s facilities and door shops located in the Western and Pacific Regions.

Since joining Boise Cascade in 2006, Sikes has held a series of key roles and progressive leadership positions in the company’s BMD division. Most recently, he was the vice president of BMD sales and marketing. Before that he was the southwest region manager, branch manager, sales manager and general line product manager. Sikes earned a bachelor’s degree in business administration from the University of Texas at Arlington. He serves on the board of directors for the Lumbermen’s Association of Texas.

“Nathan is a trusted, strategic leader with a reputation for developing talent and delivering results,” said Barney. “He is an outstanding relationship builder who personifies our motto that our business is built on relationships. I am excited to see the positive impact he will have in this new role.”

Strom said, “Nathan has a proven track record of living our values and delivering exceptional service to our customers and suppliers. This promotion reflects his outstanding accomplishments and exceptional leadership.”

Boise Cascade is one of the largest producers of engineered wood products and plywood in North America and a leading U.S. wholesale distributor of building products.

For more information, visit the company’s website at bc.com.

Bygdsiljums Sawmill Invests In Batch Kilns From Swedish Valutec

To increase quality yield and gain greater flexibility in production, Holmen, one of Scandinavia’s leading sawmill groups, has chosen to rebuild its drying fleet at its sawmill in Bygdsiljum, Sweden. An older continuous kiln is being “retired” and replaced with four state-of-the-art batch kilns from Swedish Valutec.

Holmen’s sawmill in Bygdsiljum has been producing glulam since the mid-1960s and is today one of the largest producers in the Nordic region. In addition to glulam, it also manufactures CLT and produces sawn timber.

In addition to a TC continuous kiln and three FB continuous kilns, Bygdsiljum’s Sawmill already has nine batch kilns from Valutec. The four that are now being invested in are very similar. The only difference is that the new ones are a little wider to make loading and unloading easier. Utilizing 13 nearly identical chamber dryers is an advantage for production planning as it allows great flexibility and ease in optimizing the drying programs when all the dryers have the same conditions. This makes the drying process predictable and repetitive, according to a statement from Valutec.

In connection with the investment, Bygdsiljum’s Sågverk is also upgrading to the latest Valmatics control system, “Valmatics 4.0,” for all kilns at the sawmill. Having the same control system for the entire drying fleet will make it easier for the drying operators.

For more information, visit valutec.se.

Compact Thermal Modification Plant And TMT-Certification System

Pictured is lumber after having gone through the unique Moldrup-TMT hygrothermal process.

A new smaller compact unit for thermal modification has been developed by IWT-Moldrup for annual capacities of 500,000 board feet of wood annually and was also shown at the Ligna 2025 meeting in Hannover, Germany, for the first time. The plant can use the unique Moldrup-TMT hygrothermal process which is designed to reach temperatures of up to 235 C or 455 F, for both wet and dry processes. The Moldrup-TMT hygrothermal process has advantages in:

● cycle times of 23 hours or less

● less brittleness and redundancy

● 50 percent less energy consumption compared to other processes

● 50 percent or more Co2 reduction

● a wide range of treatment processes for softwood and hardwood, which have been adapted for end-use manufacturers

● optional emission control

IWT-Moldrup is also presenting its unique third-party certification system which is based on results. The certification is for Class 2, as well as 3.1 (typically cladding) and 3.2 (typically decking) applications to provide exact information on the actual properties of thermally modified timber to the end-users.

IWT-Moldrup is a family owned and operated company in the 2nd and 3rd generation and is the world-wide leading supplier of industrial wood protection equipment, processes and systems with offices in Singapore and Denmark and representation in the US.

For more information, visit moldrup.com and biobiowood.com.

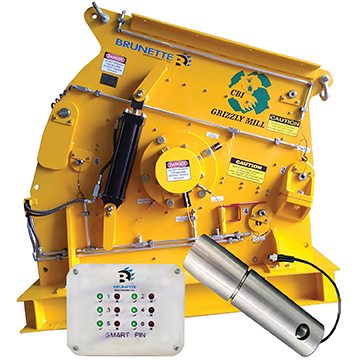

Brunette Machinery Recently Introduced The Smart Shear Pin System

Pictured, the Smart Shear Pin system for the Brunette Grizzly Mill Hog.

Brunette Machinery, located in British Columbia, Canada, recently released the new Smart Shear Pin System for the Brunette Grizzly Mill Hog. According to Kirk Forbes, CEO, the Brunette Grizzly Mill Hog is considered to be the heavy weight champion of wood-waste grinders and can process Cedar bark, stringy bark, demolition debris and log butt ends into high-quality products suitable for hog fuel, mulch or biomass products.

The Grizzly Mill’s anvil and grate are shear pin protected, but contaminated feedstock, tramp metal or large rocks can damage even the most rugged machine resulting in emergency repairs, unscheduled downtime and production delays. In order to mitigate this problem, Brunette Machinery now offers the Smart Shear Pin System as an option for new and existing Grizzly Mills.

The Smart Shear Pin system will eliminate the need for manual shear pin inspection. Each Smart Shear Pin has an internal sensor that detects damage, even invisible hairline fractures. The sensors continuously monitor the pins and send an instant alert when a crack or failure occurs. Factory-installed systems are paired with OEM software that will send alerts to a dashboard and the equipment automatically shuts down when a failure is detected. For retrofit Smart Shear Pin installations, individual pins are wired to a display box showing each pin’s status — either a green light (ok) or a red light (cracked/failed).

Forbes stated that the Smart Shear Pin System will maximize uptime, reduce costs on emergency repairs, improve safety and prevent accidents.

For more information, call 1-800-686-6679 or visit brunettemc.com.

Cleereman Industries Makes Installation At York Legacy Lumber

Paul Cleereman

Cleereman Industries Inc. along with Cleereman Controls, located in Newald, WI, recently made new upgrades and installations at York Legacy Lumber in Burkesville, KY.

York Legacy replaced their older debarker and circle mill and upgraded their log line. This project started out with a Nicholson R-2 ring debarker with Cleereman Controls.

After the Nicholson Debarker the logs travel through a Cleereman/MDI whole log metal detector and log haul that kicks onto a Cleereman heavy duty log deck. The Cleereman 42-inch bar log turner kicks logs onto a Cleereman linear positioning 42-inch tilt carriage with Cleereman Controls 3-D scanning system mounted in a new Cleereman sawyer’s booth. The carriage is pulled by a Cleereman 150HP hydrostatic carriage drive with dual cable tensioner.

The carriage runs through a Mellott 640 double cut bandmill.

Cleereman Controls did all of the control work for this entire upgrade. Cleereman Industries engineers did all the design and blueprints for this upgrade. All the equipment for this project was purchased through Cleereman Industries.

“Our unique working relationship with Nicholson Manufacturing and Mellott Manufacturing allows us to supply their equipment in our mill projects. This allows Cleereman Industries to be a one stop shop so that the customer does not have to shop around and deal with multiple vendors,” said Paul Cleereman, vice president of Cleereman Industries. “We provide all the engineering and blueprints for all machinery. Thank you to York Legacy trusting Cleereman with your equipment needs.

Cleereman Industries has been supplying sawmill equipment for over 70 years.

For more information, visit cleereman.com.

SII Dry Kilns Expands Presence with New Western States Representative

SII Dry Kilns, located in Lexington, NC, a leading manufacturer in the kiln industry, announced the appointment of a new representative to cover the Western United States. This strategic decision is part of the company’s ongoing efforts to enhance its service offerings and better serve its growing customer base across the country.

Heicor Enterprises, an experienced and well-established company based in Monmouth, OR, with a proven track record in the sales of lumber manufacturing equipment, will represent SII in the Western region.

“We are excited to expand our reach to the Western United States, and bringing on Heicor as our official representative in this region is an important step toward achieving that goal,” said Dan Mathews, Chairman of SII.

“This partnership will allow us to better serve the needs of our customers in the West and continue our growth across the nation. We are confident that Heicor will be an asset to our team and to our customers.”

Heicor Enterprises brings a wealth of experience in primary and secondary lumber manufacturing, having worked in the Western states since 2016. Their deep industry knowledge and strong network make them an ideal choice to drive SII’s mission of providing exceptional products to clients from coast to coast, stated an SII spokesperson.

As part of the expansion, SII will continue to deliver on its commitment to quality, customer satisfaction and innovation. The appointment of a dedicated Western region representative highlights the company’s focus on personalized support, ensuring clients receive the best possible service no matter where they are located, stated the company spokesperson.

SII is a leading provider of dry kilns and associated products for lumber, firewood and pallets. Based in Lexington, NC, the company has a reputation for delivering high-quality solutions and exceptional customer service. With a commitment to innovation and client satisfaction, SII has become a trusted partner for businesses across the United States.

For more information, visit siidrykilns.com or heicor.com.

The AGL Group Acquired ADA Logistics Corporation

Steve Zambo

The AGL Group, an international and domestic logistics firm headquartered in Weymouth, MA, is pleased to announce the acquisition of ADA Logistics Corporation, a domestic brokerage based in Ada, MI. This strategic acquisition strengthens AGL Group’s domestic logistics brand by adding valuable flatbed capacity and expanding its presence in the Great Lakes region.

Steve Zambo, CEO of The AGL Group, expressed enthusiasm about the acquisition, stating, “This is an exciting opportunity, as this will add strategic flatbed capacity to AGL’s growing domestic logistics brand, as well as a greater presence in the Great Lakes Region. ADA has grown a great brand over the years, and we are excited to continue to service their clients as well as create a stronger offering to our current clients.”

ADA Logistics has built a strong reputation in the industry, specializing in domestic freight solutions with a focus on flatbed transportation. By integrating ADA’s expertise and customer relationships into AGL Group’s operations, the company aims to enhance service offerings, increase efficiency and deliver greater value to customers across North America.

The acquisition aligns with The AGL Group’s commitment to growth and excellence in the logistics sector. Existing ADA Logistics clients can expect a seamless transition, with continued high-quality service and expanded resources available through The AGL Group’s extensive network.

For further information about The AGL Group and its services, please visit aglgroup.com.

Continental Underwriters Announced Andrew Belcher As New Underwriting Director

Andrew Belcher

Continental Underwriters, located in Richmond, VA, recently announced that they have named Andrew Belcher as their new underwriting director. In his new position, Belcher will oversee the management of a book of business, producing new business, as well as being involved with various programs throughout the company.

Continental Underwriters is a Managing General Agency and wholesaler providing the forest products industry in North America with a broad range of insurance and risk management solutions designed to safeguard against losses and protect the value of the businesses they insure. Their programs offer a portfolio of insurance coverages for the building materials, lumber, forest products and woodworking industries.

Belcher has been with Continental Underwriters for 12 years and was notably their very first hire. He started as an assistant underwriter, and his dedication to the company has enabled him to be promoted to the position of underwriting director. Before joining Continental Underwriters, Belcher worked for his family business where he developed his strong work ethic and learned the inner workings of how to run a business.

Belcher attended Virginia Commonwealth University in Richmond, VA, where he studied Risk Management and Finance.

He is married to his wife Tara and has two daughters.

Continental Underwriters is a member of Lake States Lumber Association, Indiana Hardwood Lumbermen’s Association, Appalachian Hardwood Manufacturers Inc., National Wood Pallet & Container Association, Hardwood Manufacturers Association, North Carolina Forestry Association, Western Wood Products Association, Mississippi Lumber Manufacturers Association, Southeastern Lumber Manufacturers Association, Great Lakes Timber Association, National Hardwood Lumber Association, Virginia Forestry Association, West Virginia Forestry Association and Wood Products Manufacturers Association.

For more information, call 804-643-7800, email andrew@contund.com or visit contund.com.