Boise Cascade Announces Troy Little As New Executive Vice President

Boise Cascade Company, located in Boise, ID, recently announced Troy Little as their new executive vice president of the Wood Products division. Little started in the forest products industry at Boise Cascade as an internal auditor in 1990. He has since spent the last 33 years with the company gaining a broad range of experience on both the financial side and the operational side, including serving as regional manager for six manufacturing facilities in Oregon.

He became division controller in 2016, financial manager in 2018, and added commodity sales to his responsibilities in 2021. He was promoted to executive vice president at the beginning of 2024.

Before joining Boise Cascade, Little graduated from Bishop Kelly High School, in Boise, ID, and earned a degree in Business Administration from the College of Idaho. Little serves on the Bishop Kelly High School Foundation and is a member of the Western Wood Products Association.

Boise Cascade Company is one of the largest producers of engineered wood products and plywood in North America and a leading U.S. wholesale distributor of building products.

For more information, visit their website at www.bc.com.

Irving Forest Products Acquires Mill Service’s Value-Added Operation in Cobleskill

Irving Forest Products (IFP), which operates sawmills in Ashland and Dixifield, ME, recently announced the acquisition of Mill Services Inc.’s value-added operation in Cobleskill, NY. The mill boasts a 100,000 square foot facility on a 15-acre plot, with warehouses to protect products from the elements. The building has supported the community for 140 years through a variety of businesses, including the agricultural industry, refrigeration modernization, window, skylight and door furnishing and supporting the war efforts of World War II. For the past 20 years, Mill Services Inc. has worked with low-grade Pine lumber and offered quality products with the help of The Home Depot to homeowners and contractors throughout the Northeast.

Cobleskill Value-Added transforms low-grade Pine into several products, including primed finger joints for use in interior and exterior applications, bevel siding (primed and unprimed), barnwood siding and other niche products. These value-added products come in a variety of paint finish options from latex to oil base.

Cobleskill Value-Added currently employs 65 people, with an intention to grow the workforce in the coming years. IFP will also be investigating opportunities to maximize mill capacity and eventually expand.

“The acquisition by Irving Forest Products not only provides our current employees with a fantastic opportunity to join a world-class organization, but also ensures that the facility here on MacArthur Ave will continue to be a partner of the local community for years to come,” said Leonard Lilly, mill manager at Cobleskill Value-Added.

Irving Forest Products looks forward to growing their relationship with the new team in Cobleskill and strengthening the current relationship with The Home Depot.

For more information, visit www.jdirving.com.

Nicholson & Cates Ltd. Welcome Dustin Wood

Nicholson & Cates Forest Products, located in Burlington, ON, has announced that Dustin Wood has joined their team as head of purchasing – Lumber Milling and Trading Division. This is the fast-growing division that is most heavily involved with NAWLA, according to a company statement. Wood was a key member of the team that organized the NAWLA event at The Montreal Wood Convention.

Wood is a fourth-generation lumberman, with his family roots in Ontario lumber camps at the turn of the last century, stretching into a retail lumber operation into the late ‘90s. Wood both studied and played music in his college years, attending Humber College in the Jazz Studies program from 2003-2005. He also worked and performed with a number of bands and musical ventures throughout Ontario and Quebec. Finally, with sawdust in his veins, Wood decided to make his own journey into the lumber business in 2005.

He climbed the ranks at Ratcliff Lumber in Gormley, ON, from stacking lumber in the remanufacturing facility, to eventually becoming operations manager. In 2010, he joined Weston Forest Products in a sales role. In his 13 years there, Wood held a few positions, finishing his time as manager of purchasing. He recognized, and is excited about, the many opportunities for additional growth within Nicholson & Cates and its new ownership regime.

Not surprisingly, with a name like Wood, he is a hobby woodworker and loves getting his hands ‘dusty’. It’s a wonder that he has any spare time at all considering that he and his wife Julia have five children ranging in age from 9-17.

Nicholson & Cates is a leading forest products distributor and manufacturer with multiple facilities in Ontario and New Brunswick.

For more information, visit www.niccates.com.

Robbins Lumber Inc. Promotes John Ritz And James Webb

Robbins Lumber Inc., located in Searsmont, ME, recently promoted John Ritz from outside sales to distribution sales manager and James Webb to wholesale sales manager.

Ritz will be managing distribution throughout the state of Maine. He has been with the company for 13 years and was with Richardson-Dana Co., of Portland, ME, which was acquired by Hood Industries, for 15 years, prior to joining Robbins. He initially started in the forest products industry as a stocker for Wilson Lumber in Concord, MA, in 1980, eventually working his way up to salesperson.

Ritz graduated high school in 1983 from Lawrence Academy, in Groton, MA, and attended Kenyon College, in Gambier, OH.

In his spare time, Ritz enjoys spending time with his family at camp and watching his twin 15-year-old girls play sports. He has been married to Kara Ritz for 31 years.

Webb has been with Robbins for 16 years and has held a variety of positions including machine operator, floor supervisor, assistant production manager, production manager and inside sales representative.

Webb attended Biddeford Adult Education, in Biddeford, ME, where he acquired his GED.

Webb serves on the Northeastern Lumber Manufacturers Association’s Marketing Committee and the North American Wholesale Lumber Association’s Northeast Regional Committee.

In his free time, Webb enjoys fishing, gold panning, firearms and craft beer.

For more information call 207-342-5221 or visit www.rlco.com.

Siskiyou Forest Products Installs System TM Finger Jointer

Siskiyou Forest Products, located in Anderson, CA, recently installed a System TM finger jointer. “We manufacture sidings and trim based around clear finger joint materials in both Cedar and Redwood,” said Darren Duchi.

Siskiyou Forest Products produces Redwood, Cedar and other Softwood exterior products designed to withstand the elements. The company primarily markets finger joint trim and siding. Siskiyou produces 800,000 to 1 million feet a month of finger joint.

The newly installed finger jointer has allowed Siskiyou to automate their finger jointing process so that it is not only faster and more efficient but has improved the quality of the operation as well. “Our goal is 30 percent gains in production and efficiency,” Duchi said.

For more information, visit www.siskiyouforestproducts.com.

Timber Products Transitions Sales Leadership

Timber Products, located in Springfield, OR, is pleased to announce that David Smith has been promoted to VP of Panel Sales in preparation of current VP of Sales, Pat Lynch’s retirement at the end of the year.

David Smith, formerly VP of composites, has been with Timber Products since 2017, overseeing the composite sales and operations teams during his time with the company. Smith is looking forward to this new role and will be working closely with Lynch over the next several months to ensure a smooth transition.

In conjunction with this transition, current Sales Managers, Kevin Smith and Davis Edwards, have been promoted to director of Western plywood sales, and director of Eastern plywood sales, respectively.

Former Director of Compliance & Marketing, Chris Knowles, has been promoted to director of international sales, a division previously overseen by Pat Lynch. Kendall Conroy, marketing manager, has been promoted to the director of marketing role.

With these transitions of sales leadership Timber Products is confident their customers will continue to receive the same top-of-class customer service from their sales team. “I have no doubt that David Smith and the sales team will continue to grow and prosper in the business,” said Lynch.

Founded in 1918, Timber Products Company produces a wide range of diversified wood products. Best known for its hardwood plywood, the company is committed to customer service, environmental sustainability and offers a fully integrated approach to manufacturing with eight manufacturing facilities, an international division and a nationwide transportation division.

Learn more at www.timberproducts.com.

Western Forest Products Completes Kiln Upgrade at Saltair Sawmill

Western Forest Products completed its first installation of a continuous dry kiln on the coast of British Columbia at the company’s Saltair sawmill. Western also plans to continue accelerating its transition to higher value products with approximately $35 million of investments for two additional continuous dry kilns.

The newly installed $12 million continuous dry kiln at the Saltair sawmill increases the mill’s capacity for continuous drying of lumber, and provides environmental benefits by reducing energy consumption. The new kiln adds to the three existing kilns on site for drying lumber. The Saltair sawmill is the largest single-line sawmill on the coast of British Columbia.

Western is the largest private employer on Vancouver Island with six sawmills and two remanufacturing plants, sustaining 3,500 jobs that support nearly 20 healthy and vibrant communities across the province. These operational upgrades are an extension of the company’s unparalleled investment in value-added manufacturing on the British Columbia coast. Over the past 10 years, Western has invested over half a billion dollars in its British Columbia operations to meet demand for sustainable, specialty building products in markets around the world.

“Our investments to modernize our mills on the B.C. coast underscore the strategic shift we are making to increase our production of value-added products with world-class facilities on Vancouver Island. The new kilns will deliver efficiency and productivity gains that further position our mills and our employees to meet the needs of our customers for high-value, specialty products over the long term,” said Steven Hofer, president and CEO of Western Forest Products.

Western is an integrated forest products company building a margin-focused log and lumber business to compete successfully in global Softwood markets. With operations and employees located primarily on the coast of British Columbia and Washington State, Western is a premier supplier of high-value, specialty forest products to worldwide markets. Western has a lumber capacity in excess of 1 billion board feet from seven sawmills, as well as operates four remanufacturing facilities and two glulam manufacturing facilities. The company sources timber from its private lands, long-term licenses, First Nations arrangements and market purchases. Western supplements its production through a wholesale program providing customers with a comprehensive range of specialty products.

For more information, visit www.westernforest.com.

Koppers Completes Acquisition of Brown Wood Preserving Company

Koppers Holdings Inc., headquartered in Pittsburg, PA, an integrated global provider of treated wood products, wood treatment chemicals and carbon compounds, recently announced that Koppers Utility and Industrial Products Inc. (UIP), a wholly owned subsidiary of Koppers Holdings, has completed its acquisition of substantially all of the assets of Brown Wood Preserving Company, Inc. and certain of its affiliates (Brown Wood) for approximately $100 million in cash. Brown Wood, which produces pressure-treated wood utility poles, will become part of Koppers UIP.

James Sullivan, President and Chief Operating Officer of Koppers, said, “The addition of the Brown Wood assets to our portfolio provides sales and production support in our existing markets. More importantly, this addition offers an attractive entry point to new geographic markets. I’m excited to get started on the integration and begin capitalizing on the combined resources of our two businesses.”

Chief Executive Officer Leroy Ball added, “I am happy to be closing on this acquisition and welcoming the Brown Wood team into the Koppers culture. We continue to see the utility pole market as an attractive growth engine for Koppers, given UIP’s smaller exposure relative to our other businesses. As well, we anticipate that positive industry dynamics will support a healthy end market in the utility pole business for the foreseeable future.”

The transaction is expected to contribute $15 million to $25 million in earnings before interest, taxes, depreciation and amortization (EBITDA) in 2025. Details of the impact on 2024 will be provided during the company’s first-quarter earnings call in early May.

For more information, visit www.koppers.com.

Canada’s Second TC-Continuous Kiln Is Now In Operation

Recently, the first lumber packages were loaded in Spruce Product Limited’s (SPL) new continuous kiln from Swedish Valutec. The TC continuous kiln has eight drying zones and a yearly capacity of approximately 60 million board feet.

“We enjoyed a truly great collaboration where we were able to work together with extremely capable employees on site,” said Andreas Lövgren, Production Manager at Valutec in charge of commissioning along with commissioning technician William Marklund.

Canadian SPL, located near Swan River, Manitoba, is a manufacturer of premium lumber and wood products for the construction industry and the integrated wood products industry. Using the latest technology available, every aspect of the log is used in the product lines. SPL has been supplying products for Canadian and International markets since 1942.

Since Valutec’s TC continuous kiln has been introduced, it has achieved great success on the world’s sawmilling markets, according to a company spokesperson, it is a kiln type that comes with distinguishing features such as low energy consumption, high flexibility and superior capacity. It gives the operator the possibility to create the ultimate drying process with unlimited freedom to mix dimensions, minimal moisture content variation and reduced risk of checking. Annual capacity can reach 125 million board feet with target moisture contents down to around 12-18 percent.

“Our TC model continuous kilns represent an entirely different product compared to the existing lumber kilns on the North American market,” explained Mattias Henriksson, Valutec’s assembly manager. “What’s more, we also offer world-leading process control with our Valmatics 4.0 control system. It invites discussions on issues such as drying schedules for specific types of lumber, or managing situations where we need to optimize the energy load as other parts of the sawmill are also operating near capacity.”

The TC kiln is probably the market’s most sustainable timber kiln. Constructed in stainless steel, resistant to thermal expansion and fatigue, the kiln has superior longevity and requires minimal maintenance. Studies show that Valutec’s stainless steel TC continuous kiln emits 23 tons less CO2 per year than the correspondent kiln built in aluminum. 23 tons of CO2 is about as much as three hectares of coniferous forest absorb in a year.

For more information, visit www.valutec.se.

Arxada Introduces AntiBlu® M3 And Thriving Partnership with ICONX And Zee Water And Energy

AntiBlu® M3, part of the AntiBlu® product line from Arxada, headquartered in Basel, Switzerland, is now available in Canada. It offers a one pack, blended formulation with three active ingredients to provide superior protection for control of sapstain, mold, and decay fungi on freshly sawn lumber and other wood products. This robust formulation is intended for the entire Canadian market and is ideal for both Softwood and hardwood mills seeking superior, longer-term protection from a single, service-oriented supplier.

The ingredients IPBC, propiconazole and DDAC quat have a wide range of mold and fungal control applications across numerous industries but the combination of these actives for the anti-sapstain market is only available in AntiBlu® M3.

The AntiBlu® product line, including Mycostat®, encompasses many product options, each intended for specific conditions and applications. For more information, reach out at wolmanizedwoodinfo@arxada.com or visit antiblu.com.

In other news, Arxada partnered with ICONX and Zee Water and Energy to promote and sell anti-sapstain products into the sawmill industry. Since its initial pairing, in 2023, the team reviewed the market and its needs and has developed a strategy to meet demands and expectations with each partner providing either logistical or product support. The partners recognized the need to better reach the industry to provide wood protection products, especially in the Southeast and Northeast.

The product offering, manufactured by Arxada for the protection of freshly sawn and seasoned logs, poles, posts, and lumber for decades, helps with the control of sapstain, mold, and decay fungi, allowing sawmills to ship clean and bright wood to wood treaters, jobsites, and lumberyards. ICONX and Zee work directly with buyers to determine what products from within the anti-sapstain line will work best for that buyer. To learn more, reach out to us: Brian Delbrueck (brian.delbrueck@arxada.com); Miles Stoffer (miles@iconxchemicals.com); or Scott Bookout (scott.bookout@vincitgroup.com) or visit antiblu.com.

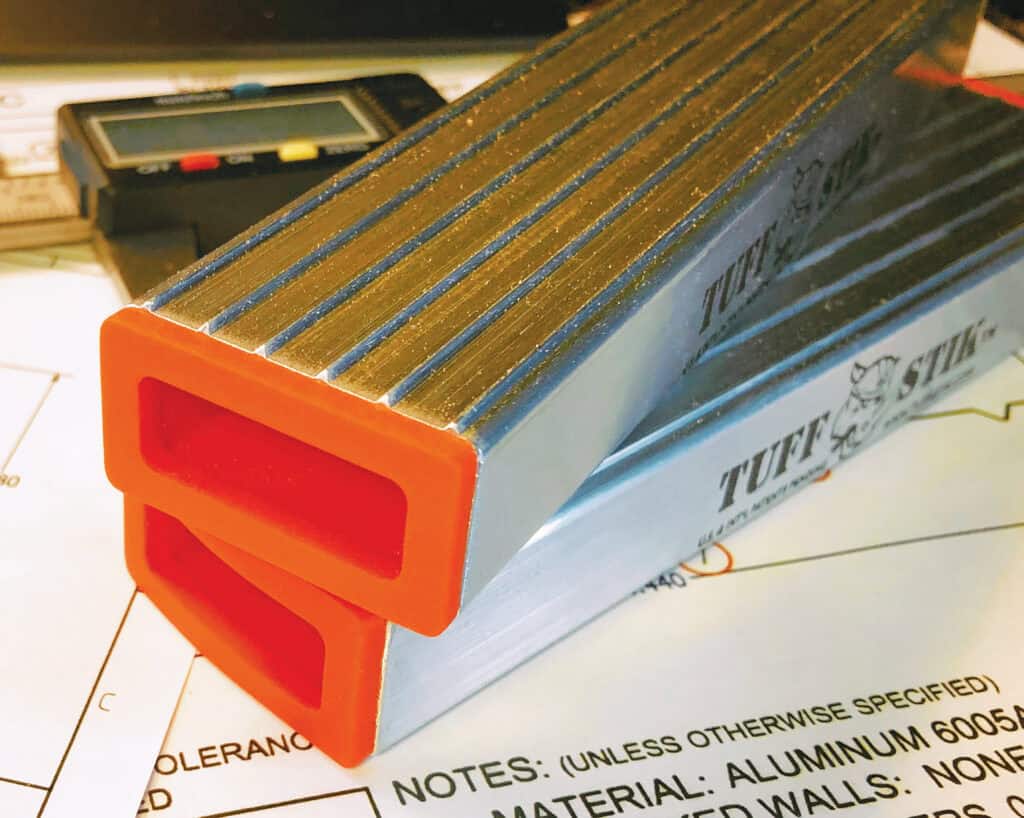

TUFF-STIK™ Announces Their New Dry Kiln Sticks

TUFF-STIK™, located in Ellisville, MO, recently announced their new TUFF-STIK™ dry kiln sticks. These new dry kiln sticks provide an unmatched durability and performance compared to traditional wooden sticks, according to the company. Their new sticks offer a better grip on lumber while evenly conducting heat, and lasting over 500 turns, with some of their prototypes exceeding 600 turns.

These sticks were designed with direct input from mills, they are aluminum-alloy sticks that remain straight while eliminating the need to slow down stacker speed. These new sticks allow for TUFF-STIK’s™ customers to minimize cleanup and disposal hassles while streamlining operations.

Securely gripping lumber top to bottom, TUFF-STIK™ minimizes deterioration during drying, leading to higher-quality results and increased profits for their customers, said a company spokesperson. These new sticks are also 100 percent recyclable, retaining up to 50 percent of their original raw material cost at the end of their service life.

For more information, visit www.tuff-stik.com to learn more.

perfect solution that is easy to use and produces premium wood products.

Wood-Mizer Introduces the MP280 4-Sided Planer/Moulder

Capturing the growing interest of the professional woodworker movement, Wood-Mizer, located in Indianapolis, IN, introduced the versatile MP280 4-Sided Planer/Moulder. The MP280 planer/moulder joins the established Wood-Mizer range of woodworking products that includes jointer/planers, two-sided planer/moulders, four-sided planer/moulders, slab flattening machines, dust collection systems, planer blades, moulder knives, table saws and more.

The MP280 is a versatile and compact machine for professional woodworkers that planes and moulds material on all four sides at one time. This all-in-one machine is easy to use and produces premium wood products. Made of a cast iron table, robust steel frame and high-quality components, the MP280 includes one horizontal top cutter, one horizontal bottom cutter, and two vertical side cutters for planing and moulding on the top, bottom and sides of material at the same time with each pass. All four cutters can be fitted with planing knives or moulding profile knives to produce flooring, planed boards, crown moulding, cabinet trim, paneling, door and window frames, furniture components and more.

“Wood-Mizer is committed to providing our customers with the equipment necessary to process material from forest to final form. With its exceptional value and premium components, the MP280 is perfect for woodworkers who value precision, affordability, and the versatility to complete projects from trim and flooring to furniture,” said Chad Sanders, Wood-Mizer Woodworking Product Specialist.

Compared to the popular MP260 planer/moulder, the MP280 features multiple upgrades for durability and performance including reinforced metal construction, standard infeed and outfeed tables, longer infeed fence, additional cutter head and dust collector controls and more.

Since 1982, Wood-Mizer has served more than 100,000 customers throughout the world From Forest to Final Form®, Wood-Mizer offers an extensive line of equipment including narrowband portable and industrial sawmills, wideband sawmilling equipment, band resaws, board edgers, wood kilns, planer/moulders, firewood processing equipment, pallet recycling equipment, material handling equipment, sawmill blades and blade maintenance equipment for woodworking and forestry hobbyists and professionals all over the world.

Visit www.woodmizer.com for more information.

ITOCHU Building Products Holdings, Inc Announces Leadership Changes

ITOCHU Building Products Holdings, Inc. (IBP), located in Dallas, TX, recently announced leadership changes within its group companies which were effective May 1, 2024.

Kobe Yamamoto, with a 20-year tenure in the United States across diverse leadership roles within IBP and its subsidiaries, is set to embark on a new journey back to Japan. There, he will assume a leadership position within ITOCHU Corporation, the overarching parent company of IBP. Throughout his tenure, Yamamoto has consistently demonstrated exemplary leadership, made significant contributions to the organization’s prosperity and expansion and been a champion for the building products and fencing industry, according to a company representative.

Scott Suh, currently the Chief Executive Officer of Alta Forest Products and Chief Strategy Officer of IBP, will become the new Chief Executive Officer of IBP. Suh joined ITOCHU International Inc. (III) in 1996 and transferred to the current Division Company in 2002. He spent the first 10 years of his tenure at III-NY supporting the various business units prior to being seconded to multiple operating companies in an executive managing role over the last 18 years. He will continue to pave the path for IBP and its subsidiaries to diversify, grow, and remain profitable, said a company spokesperson.

James Venters, currently the Vice President of Sales for Alta Forest Products, will take over as CEO of Alta Forest Products. Venters has been with Alta for 21 years and during his tenure, he has led the company’s sales and marketing efforts to firmly establish Alta as a supplier of Western Red Cedar fence pickets in the market and has strengthened and grown the relationship with key customers across North America, according to a company spokesperson.

For more information, visit www.ibholdings.com or www.altafp.com.

Code Conforming Wood Design Now Available

The 2021 Code Conforming Wood Design (CCWD), in Leesburg, VA, a joint publication of the American Wood Council (AWC) and the International Code Council (ICC), is now available as a free download. The publication summarizes the key provisions related to the use of wood and wood products as they appear in the 2021 International Building Code (IBC).

“The motivation behind the development of the CCWD is to provide code officials with a concise resource on basic requirements affecting wood use in the IBC,” said Philip Line, AWC vice president of codes and regulations.

The 2021 CCWD details new code provisions from the 2021 IBC including:

- Significant changes to Type IV construction with the introduction of three new types of mass timber construction (i.e., Type IV-A, Type IV-B, Type IV-C) and the renaming of the original Type IV as Type IV-HT.

- Revision of Section 506.2 on allowable area determination to include specific sections for single-occupancy buildings and mixed-occupancy buildings and introduction of Table 506.3.3 as a replacement to the weighted average calculation for frontage increase factors.

- New requirements in Section 3313 for water supply to be provided prior to commencement of the above ground framing.

“The main goal of the CCWD is to compile the occupancy and height and area provisions of the IBC for wood structures into one easy to use publication,” said Code Council Executive Vice President of Content and Services Mark Johnson. “We are pleased to partner with the American Wood Council to share this valuable information to aid in the safe and sustainable construction of wood buildings.”

The 2021 CCWD, along with 2018, 2015, 2012 and 2009 versions, can be downloaded for free on the AWC website, www.awc.org.

C&D Lumber Co. Announces Closure

The Board of Directors of C&D Lumber Co. announced the permanent closure of the company’s operations. Founded in 1890 by Alfred Johnson in Southern Oregon’s Coos County, C&D Lumber has been a cornerstone of the timber industry for over 130 years, renowned for producing high-quality Douglas Fir, Incense Cedar and Port Orford Cedar wood products.

The company, a sixth generation family-owned and operated business, has weathered many storms through the decades. However, the unprecedented challenges facing the industry today – from market fluctuations, increasing operational costs, to timber supply issues – have made it impossible for the company to envision a sustainable future, stated a company spokesperson.

C&D Lumber’s legacy is deeply entwined with that of the Riddle community and beyond. For more than a century, according to the company, it has not only been a leading employer but also a fervent supporter of local initiatives and stewardship of their natural resources. The Johnson Family plans to continue this tradition through the continued management and growth of C&D Lumber’s sister company, Silver Butte Timber.

The immediate plan involves a strategic wind-down of operations, ensuring that all remaining inventory is processed and sold and affairs are settled responsibly and respectfully. The company is committed to providing support to their employees during this transition, including severance packages and assistance in finding new employment.

For more information, visit www.cdlumber.com.