Industry News

New Machinery Installed At Thompson River Lumber

Thompson River Lumber Co. in Thompson Falls, MT, recently installed a Weinig moulder at their production facility.

The moulder works with material up to eight inches wide and can process 330 feet a minute. With this moulder, the company will be producing multiple patterns. Packaging full size, half packs and quarter packs are services offered by the company.

Species processed by Thompson River Lumber are Engelmann Spruce, Ponderosa Pine, Lodgepole Pine, Douglas Fir, Larch and White Fir.

A fully automated shavings plant is now operational and offering bagged shavings to the marketplace.

Thompson River Lumber is a one-stop-shop that that has been in business for over 35 years. The company serves customers across the United States and exports products to Mexico.

Thompson River Lumber Co. is a member of the Montana Wood Products Association, the North American Wholesale Lumber Association, the Western Wood Products Association, which is their grading agency, the American Forest Resource Council and the Timber Products Manufacturers Association.

Visit thompsonriverlumber.com for more details.

West Bay Forest Products Gains Two New Salesmen

Brendan Henits

After completing a part-time practicum that lasted nine weeks, Brendan Henits recently joined Langley, BC-based, West Bay Forest Products on a full-time status as a sales representative.

Henits’ responsibilities include developing new customers, maintaining relationships, providing tailored product solutions to meet customer needs and identifying market opportunities.

Prior to his first position in the forest products industry at West Bay Forest Products, Henits worked numerous roles such as a carpenter’s hand at Mansouri Design in Vancouver, BC, a greens worker for IATSE Local 891 in Burnaby, BC, and a landscaper with the City of Burnaby. He has also been a baseball instructor at Vancouver, BC-based, T21 Performance.

Henits attended high school from 2013 to 2018 until he received his diploma from Sutherland Secondary in Vancouver, BC. He studied at the Division I, New Mexico Junior College from 2018 to 2020 and graduated with a General Studies degree. He started his path toward a diploma in Marketing/Marketing Management in 2023 at the British Columbia Institute of Technology and graduated in 2025.

Since childhood, Henits played hockey and baseball. He continued playing baseball at New Mexico Junior College and now, he is a member of the men’s hockey and slow-pitch softball leagues. He also enjoys golf and tennis. When Henits is not on the field or the ice, he can be found at the gym, with his lovely girlfriend or spending time with friends.

Jackson Caelian

In other news, West Bay Forest Products also hired Jackson Caelian as a sales representative tasked with developing new markets. Caelian was officially hired around the same time as Henits and was an intern from March until June of 2025.

This is Caelian’s first job in the forest products industry.

He received a high school diploma at Delta, BC-based, Seaquam Secondary School, where he attended from 2018 to 2023. For the next two years, he also attended the British Columbia Institute of Technology where he received a diploma in Marketing and Management (Professional Sales).

Caelian enjoys working on cars, golfing and playing guitar with his friends.

West Bay Forest Products offers the following products in Western Red Cedar: timbers, boards, pattern stock, fencing, decking, rougher-headed dimension and more.

Call 604-881-2839 to reach Henits or 604-262-1064 to reach Caelian. Visit westbayforestproducts.com for more details.

RoyOMartin Announces Executive Leadership Transitions

Jeremy Burford

Jeremy Burford, the vice president of plywood, was recently promoted to the role of executive vice president of manufacturing and sales at RoyOMartin in Alexandria, LA.

Burford will continue his leadership of the Chopin, LA-based, plywood facility and timber mill, Martco L.L.C. He will also assume more responsibilities of the Martco L.L.C. OSB facility in Oakdale, LA, the Corrigan OSB, L.L.C. in Polk County, TX, in addition to ROMEX, RoyOMartin’s sales and marketing division.

Cade Young

In other news, Cade Young, formerly the vice president of land and timber, was recently promoted to executive vice president of Martin Timberlands LLC and the company’s supply chain. His new responsibilities for leading the supply chain involve purchasing and logistics throughout the organization.

His promotion and new tasks are additions to his current duties, which include his continued leadership of RoyOMartin’s timberland operations, Martin’s mineral division and Walsh Timber Company L.L.C., which is headquartered in Zwolle, LA.

The expertise of both Burford and Young will help ensure the continued excellence, innovation and service that the company’s customers have come to expect, according to a company statement. Both will report to President and Chief Operating Officer E. Scott Poole.

Martco L.L.C. is a subsidiary of Martin Sustainable Resources L.L.C., the Martin family-owned parent to several companies that focus on land, timber and mineral resources, emphasizing sustainable forestry and the manufacture of forest products. It is best known by its trade name, RoyOMartin, which honors the entrepreneurial spirit of Roy O. Martin Sr., who began the family’s first business (a sawmill operation) in 1923.

RoyOMartin currently operates two manufacturing facilities in Louisiana. A third facility is operated in Texas by its wholly owned Texas subsidiary.

RoyOMartin has 1,400 employees and is, as noted by a company representative, “a leading employer in every region in which we operate.”

Visit royomartin.com for more.

BPWood’s Fresh Face In Sales

Lara Damen

Lara Damen was recently hired as a lumber trader to handle Douglas Fir sales and business development at BPWood in Vancouver, BC.

BPWood is a worldwide specialty company that offers boards, patterns, dimensions and timbers in coastal species. They also import finger jointed, edge-glued, Clear Vertical Grain Western Red Cedar in addition to Japanese Cedar, ThermoWood and primed, finger jointed, edge-glued Radiata Pine.

Damen described the company as “small and nimble with a wide reach. BPWood has exceptional abilities to source the weird and wonderful products customers may be looking for.”

Damen has been in the forest products industry for five years and got her start at Western Forest Products as a sales and marketing intern. Through a co-op program at the University of British Columbia in Vancouver, BC, she worked at many Western Forest Products mills on Vancouver Island before moving to the Western Forest Products head office in Vancouver for a Cedar sales position.

At the University of British Columbia, she earned a Bachelor of Science degree in Wood Products and Processing.

In her spare time, she explores British Columbia on foot, with her bike or in her four-wheel drive vehicle.

BPWood is a member of the Western Red Cedar Lumber Association, the North American Wholesale Lumber Association, the International ThermoWood Association, the British Columbia Wholesale Lumber Association, the National Hardwood Lumber Association, the Independent Wood Processors Association of British Columbia and the Pacific Lumber Exporters Association.

To learn more, call 604-830-0694, email lara@bpwood.com or visit bpwood.com.

Nyle Completes Installation Of Two High-Performance Kilns At Hancock Lumber

Pictured is a newly installed Nyle dry kiln at Hancock Lumber.

Nyle Dry Kilns is excited to announce the successful installation of two advanced dry kilns at Hancock Lumber’s locations in Casco and Pittsfield, ME. These installations represent a significant step forward in Hancock Lumber’s commitment to efficient, high-quality lumber drying and sustainable operations.

Each kiln is specifically designed for drying Eastern White Pine and features a biomass-powered steam heating system, which ensures energy efficiency and environmental responsibility. Nyle’s state-of-the-art kiln control system provides precise temperature and moisture control, optimizing drying cycles and enhancing overall lumber quality.

Equipped with heat recovery technology, advanced airflow systems, and precise automation, these kilns will help Hancock Lumber achieve greater consistency in drying, reduced energy consumption and enhanced operational efficiency.

Nyle takes pride in its continued partnership with Hancock Lumber, delivering industry-leading drying solutions that promote performance, sustainability and long-term value.

For more information about Nyle Dry Kilns and their customized lumber drying solutions, please visit nyledrykilns.com.

TechWood Announces ARCAT Certification For Architects And Engineers

Matt Visconti

TechWood, a leader in innovative protective lumber treatments, has recently announced that their protective solutions are now available for specification on ARCAT, an industry-approved platform that provides resources for architects, engineers and design professionals. It offers a vast library of building product information, including CAD details, BIM content and material specifications, helping professionals during the design and construction process.

As Techwood continues to focus on helping drive better building and construction, the TechWood 2200, 2200EX, 3300 and 4400 lumber treatments can now be applied to advance project planning efforts, allowing architects and engineers a new choice of protected materials for framing packages that resist mold, rot, deformation, termites and are Class A fire rated.

“In addition to our continuing accredited education courses through AIA (American Institute of Architects), we are now pleased to provide our lumber treatments to architects and engineers looking to build safer, cleaner, and better homes for the future,” said Matt Visconti, senior market development manager for TechWood. “Better materials are available to improve construction, and we’re focused on delivering them to the market from sill plate to truss.”

Companies that are currently in the planning stages of a new building project, whether it be residential, commercial, or multi-family and are looking for a fully protected, eco-friendly and high-performance lumber solution, can visit ARCAT to review TechWood’s specifications, call 1-833-TEKWOOD or go to techwoodtreatments.com.

KDS Windsor Launches New Industrial Mechanical Group

KDS Windsor, a leading manufacturer of lumber drying systems, has officially launched its Industrial Mechanical Group, expanding its capabilities to meet the growing demand for expert field service, maintenance, and mechanical installation work across the wood products industry.

With over 100 Continuous Dry Kilns (CDKs) in operation globally, KDS originally built its service team to support its systems in the field. But over time, customer needs evolved, and so did KDS. What began as a support crew for CDK customers has evolved into a full-service mechanical division, now available to serve mills of all types, regardless of whether they own KDS equipment, according to a company statement.

Today, KDS Windsor operates five dedicated mechanical crews and has over 100 skilled professionals in the field, providing a range of services that include kiln rebuilds, equipment installation, fabrication and welding services, as well as air control and material conveying systems. That’s a major differentiator in an industry where most manufacturers outsource services, or, in some cases, don’t offer any support services at all. At KDS, the people who build the equipment are also the ones who maintain it.

“We kept hearing the same thing from customers: ‘We trust you more than anyone else to touch this equipment,’” said a KDS field supervisor.

The Industrial Mechanical Group offers:

- Preventive maintenance and service contracts

- Emergency repairs and on-site troubleshooting

- Kiln rebuilds, burner retrofits and ductwork fabrication

- Steam/thermal piping, refractory systems and structural steel installation

Backed by in-house fabrication, fully equipped service trucks, and a team of seasoned kiln experts, the Mechanical Group combines boots-on-the-ground speed with deep product knowledge, according to a company representative.

Need support for a mill? Contact KDS at (828) 891-8115 or visit kdswindsor.com to schedule a service consultation.

Comact Launches New Wide Board Lug Loader

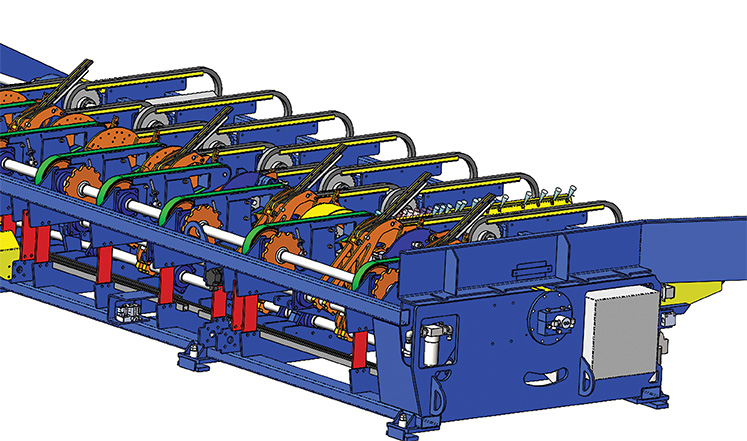

Wide Board Lug Loader

Comact, a global leader in wood processing solutions located in Saint-Georges, QC, recently announced the launch of the Wide Board Lug Loader, a next-generation system engineered to handle oversized boards with cross-sections of up to four-inches x 22-inches. Building on the proven fundamentals of Comact’s industry-renowned lug loader, this new design addresses the growing need for high-performance solutions in specialty product manufacturing.

With a patent-pending design and a speed of up to 70 lugs per minute, the Wide Board Lug Loader ensures precise and efficient board handling, while maintaining the reliability and throughput customers expect from Comact systems.

Simon Potvin

“Innovation is at the core of who we are,” said Simon Potvin, CEO of Comact. “This new lug loader was developed in direct response to the needs of our customers producing specialty products, where traditional handling equipment reaches its limits. It’s a great example of how we continuously evolve to provide tailored, cutting-edge solutions that help our clients stay ahead.”

The Wide Board Lug Loader is the latest step in Comact’s ongoing mission to deliver more flexible technologies that meet the real-world demands of today’s mills, and tomorrow’s, according to the company.

For over 100 years, Comact has been a leading OEM in high-caliber wood processing equipment, digital technologies, cutting solutions, project services and aftermarket support. Driven by innovation and excellence, Comact is dedicated to helping customers address their most pressing operational and business challenges in today’s industry.

Whether for brownfield or greenfield projects, Comact’s expertise provides wood processing facilities with the confidence that their investments will yield superior performance, throughput, and ROI according to a company representative. This ensures they remain competitive and achieve sustained growth in an ever-evolving market.

“Trust Comact to deliver exceptional performance every time,” added a company representative.

For more information, visit comact.com.

Refresh And Renew Wood With AntiBlu® Renovare™ Products

The lumber on the right was sprayed with AntiBlu® Renovare™ RTU in a controlled environment at a sawmill, while the lumber on the left from the same pack did not receive the treatment.

Arxada, headquartered in Basel, Switzerland, recently announced the release of AntiBlu® Renovare™ Renew and Refresh, which can be found through Arxada’s Rocky River, OH-headquartered, partner River City Wood Products LLC.

The new product, which was created to combat mold on seasoned wood, has been described by an Arxada representative as “an acetic solution that cleans and brightens wood by a rapid chemical reaction with molds, wood sugars and extractives which removes surface stains and other blemishes. The reaction is accelerated by ultraviolet light and causes no detrimental effects to wood surfaces.” In addition, AntiBlu® Renovare™ is also “more effective at reducing surface blemishes such as mold and mildew and has a more enduring effect than bleach treatments.”

The new cleanser is specially formulated to be an effective, organic, non-toxic and environmentally friendly combination of food grade chemicals for wood product rejuvenation and restoration.

AntiBlu® Renovare™ is available in concentrate with concentration dilution options for application versatility. It is also available in ready-to-use formulas from the manufacturer.

Email wolmanizedwoodinfo@arxada.com for more product information or visit arxada.com. For purchasing details or a demonstration, contact Kevin McLaughlin with River City Wood at kmm@rivercitywood.com or visit rivercitywood.com.

AWC Releases U.S. Northern Softwood Lumber EPD

Rachael Jamison

The American Wood Council (AWC), located in Leesburg, VA, recently released a new Environmental Product Declaration (EPD) for U.S. softwood lumber in the Northern region. This EPD rounds out the U.S. wood products industry’s first regional softwood lumber EPDs. Previous industry EPDs had been North American in scope, and last year, AWC released the first regional U.S. EPDs for softwood lumber in the Pacific Coast, Inland Northwest and Southern regions.

“AWC, driven by member feedback, recognized that the market wanted more granular data for our products’ environmental impact, and the publication of this final, regional EPD demonstrates our industry’s commitment to transparency and further shows the sustainability of U.S. wood products,” said Rachael Jamison, AWC’s vice president of markets and sustainability.

To develop the four regional EPDs, AWC partnered with the Consortium for Research on Renewable Industrial Materials and the National Council for Air and Stream Improvement. The data was gathered from AWC’s annual Life Cycle Survey which collects mill-level data before being aggregated and analyzed in Life Cycle Assessments (LCAs). These LCAs then form the base of the EPDs. Once completed, the EPDs went through third-party verification by the American Society for Testing and Materials.

All four regional EPDs (Northern, Pacific Coast, Inland Northwest and Southern) are available to view online, along with other AWC-managed industry EPDs including softwood plywood and oriented strand board.

The American Wood Council represents 86 percent of the structural wood products industry and the almost 465,000 men and women working family-wage jobs in mills across the country. From dimension lumber to engineered wood products, AWC champions the development of data, technology, and standards to ensure the best use of wood products and recognition of their unique sustainability and carbon-reduction benefits. They are leaders in providing education to the design, code and fire official communities who view AWC as a trusted and credible resource.

Email @woodcouncil or visit awc.org for more information.

TP Trucking & Logistics Expands Into The Houston Market

Joe Chapman

TP Trucking & Logistics, located in Central Point, OR, recently announced the expansion of their warehousing and logistics capabilities. On August 1st, TP Trucking & Logistics was set to assume the property lease and customer base of an existing transload facility in Pasadena, TX just outside of Houston.

The new facility has 140,000 square feet of indoor warehouse, approximately seven acres of outside storage, 16 dock high doors for container and van loading, and two inside loading docks for flatbeds. The product mix this facility can serve includes super sacks, IBC totes, lumber and panel products, steel coils and other miscellaneous metal and fiber products.

In addition to transload and warehousing services, the facility has an open switch rail track served by the PTRA railway network allowing for the ability to receive all Class I railroads in North America. This site will have the ability to load and unload bulk railcars, open-top gondolas, center beams, flat cars and box cars.

The new Houston facility will not only be a transload center, but it will offer new local, regional, and OTR freight opportunities for TP Trucking & Logistics. “Establishing ourselves in this major market area will assist us in achieving short, mid, and long-term goals for trucking and logistics,” said Joe Chapman, general manager of Warehousing & Logistics.

The new location will work in conjunction with TP Trucking & Logistics’ partner company Timber Products, extending their domestic business by offering additional reloading services as they continue their growth in the central United States. It will also provide Timber Products’ international division and other customers with convenient access to the port of Houston, the 5th largest container port, and the dominant port for the Gulf States comprising 74 percent of the market share.

TP Trucking & Logistics is committed to growth and is very excited to operate in this new market.

Founded in 1964, TP Trucking & Logistics has provided quality service and award-winning safety for over 60 years.

With operational locations in Oregon, Georgia, and Texas, TP Trucking & Logistics runs in the lower 48 states, plus Canada with a diverse fleet of trucks. No matter the task, TP Trucking & Logistics works hard to get the job done right. For any questions or transload inquiries, please contact Joe Chapman at 762-309-1007 or visit tptrucking.com.

Founded in 1918, Timber Products produces a wide range of diversified wood products. Best known for its hardwood plywood, the company is committed to environmental sustainability and offers a fully integrated approach to manufacturing with nine manufacturing facilities, an international division, and a nationwide Trucking & Logistics company, 800-777-1121 | tptrucking.com.

Learn more at timberproducts.com.