Culpeper Acquires Fortress Wood

Culpeper Wood Preservers, located in Culpeper, VA, recently acquired Fortress Wood Products, a North Carolina-based premier wood supplier and pressure treater. This acquisition strengthens Culpeper’s presence in the Mid-Atlantic while expanding its capacity to deliver premium pressure-treated wood products to its customers.

“The acquisition of Fortress Wood Products is a key move in our growth strategy to best serve our customers,” said Jonathan Jenkins, president of Culpeper Wood Preservers. “Fortress embraces the same values as Culpeper, including a commitment to teamwork, customer service, innovation, trust and professionalism. We are thrilled to strengthen our foothold in this region alongside Fortress’ existing, hard-working, dedicated staff.”

Fortress Wood Products was founded in 1986 as a division of The Lester Group. Initially located in Greensboro, NC, the company expanded its operations to facilities in High Point, Henderson and Elizabeth City.

“We have full confidence that the Fortress Wood business we have built over the last nearly 40 years is in very capable hands with the Culpeper team. Fortress customers will get the same level of top-tier service and high-quality pressure treated wood that they have come to know and expect,” said Jay Dickens, president and CEO at The Lester Group.

Culpeper Wood Preservers is one of the largest producers of pressure treated lumber in the United States. In 1976, Culpeper Wood Preservers started from a single location in Culpeper, VA. Today, the company is a leading manufacturer of pressure-treated products for the residential, commercial, industrial and marine markets. Culpeper Wood Preservers’ brand name products are sold exclusively through independent lumber dealers throughout the Mid-Atlantic, Northeast, Midwest and South.

For more information, visit www.culpeperwood.com.

Elk Creek Forest Products Welcomes Leslie Southwick

Elk Creek Forest Products, located in McMinnville, OR, recently welcomed Leslie Southwick as their new sales account executive and marketing manager. Southwick is responsible for developing, implementing and overseeing marketing strategies that promote the company’s products and services, enhance Elk Creek’s brand visibility and drive business growth through key accounts.

Elk Creek’s product line ranges from green framing lumber, 1-inch boards, to providing premium dry and green Douglas-Fir timbers. According to Southwick, if you are looking for something unique or out of the norm in Douglas-Fir then Elk Creek is the right company to call to find it for you. Southwick has been in the forest products industry since 2008 where she started at C&D Lumber, there she worked as sales and marketing manager. Before joining the forest products industry, Southwick worked as a marketing manager for a shopping center.

Southwick graduated from South Albany High School, Albany, OR, in 1996. She then went on to earn a Business Administration degree with a concentration in marketing and a minor in communications from Oregon State University. She also earned a certificate in digital marketing from Oregon State University.

Southwick is a member of the North American Wholesale Lumber Association (NAWLA), a volunteer for the Traders Market Planning Committee for NAWLA and has served as vice-chair of the Umpqua Valley Lumber Association.

In her spare time, she enjoys spending time with her family and friends in the outdoors while camping, hiking and boating. She loves to read and spend time with her three daughters, two grandsons and one granddaughter. She has been married to Alan Southwick for 16 years.

For more information, call 503-474-4446 or visit www.elkcreekforest.com.

Hancock Lumber Named Three New Executives

Hancock Lumber, located in Casco, ME, recently repositioned itself as a ‘division-less’ organization. As the company continues to grow and evolve, this restructuring is designed to help meet current and future business demands, execute strategic initiatives, and foster collaboration and alignment companywide. The company remains all-in on being a world-class White Pine manufacturer and adding value to those products, on servicing builders through its lumberyards and kitchen design showrooms, and on being a market leader in component manufacturing with trusses, wall panels, and Tiny Homes—but, above all, on honoring its mission to enhance the lives of the people who work at or are connected to Hancock Lumber. As part of this change, the company welcomed two new members to its executive team and announced a significant internal promotion.

Mark Hopkins was named companywide chief operating officer. In this role, Hopkins has direct responsibility for all locations—including the company’s three Eastern White Pine mills—to help drive a consistent experience across culture, people, safety, sales and operations. Hopkins joined Hancock in 1996, working as a Counter Pro in Yarmouth. He went on to become an account manager until being named the Bridgton, ME, general manager in 2012. Hopkins transitioned to retail sales manager in January 2015 before being named Chief Operating Officer for retail in September 2015.

Hillary Roy was named chief people officer. Following over two decades and many leadership roles at Hannaford, Roy joined the executive leadership team in October 2024 as chief people officer due to an internal move in Hancock Lumber’s Human Resources department. In addition to overseeing 15 stores with direct responsibility for the employee experience, safety and talent development, Roy helped develop, launch and support scalable and sustainable people-focused programs across the entire Hannaford organization.

Rebecca Hatfield was named chief strategy and revenue officer. The chief strategy and revenue officer is a new role that was created to expand Hancock Lumber’s executive team’s capacity and help execute on strategy and revenue generation. Hatfield joins Hancock’s team with a career in finance, strategy, real estate development, construction services, property management and leadership—most recently serving as president and CEO of Avesta Housing.

With this leadership transition, Mike Shane will be assuming a new role leading White Pine manufacturing operations overseeing Bethel, Casco and Pittsfield in conjunction with site general managers. Matt Duprey, chief sales officer – White Pine, will continue to manage the company’s White Pine customers and sales.

Hancock Lumber is a seventh-generation, family owned integrated forest products company. The company operates high-efficiency white pine mills, a network of lumberyards, truss and wall panel manufacturing facilities and full-service kitchen design showrooms, Team Hancock is led by over 700 employees.

For more information, visit www.hancocklumber.com.

RoyOMartin’s OSB Facility Expansion Recently Held Its Grand Opening

Martco LLC (RoyOMartin), located in Corrigan, TX, recently celebrated the grand opening of the expansion of Corrigan OSB LLC, RoyOMartin’s Texas subsidiary. This enlargement makes the oriented strand board (OSB) manufacturing facility the largest of its kind in North America. The event emphasized the facility’s impact on increasing OSB production and creating local jobs, as well as the regional and national housing market.

Constructed next to the company’s original state-of-the-art OSB plant, the new expansion is located in Corrigan between Lufkin and Livingston. The second facility significantly increases the mill’s size and production capacity to 1,400 million square feet, approximately 75 percent increase, annually and now provides a total of 300 jobs at the mill.

RoyOMartin Chairman and CEO Roy O. Martin III, in his address proudly stated that, “It’s obvious that our first plant succeeded here in Corrigan, and now you have two plants employing almost 300 skilled individuals and supporting seven times that number in logging, transportation, maintenance and other support roles. We look forward to many decades of mutual success, paying great wages so families can thrive here.”

Martco LLC is a subsidiary of Martin Sustainable Resources LLC, the Martin family-owned parent to several companies that focus on land, timber and mineral resources, emphasizing sustainable forestry and the sustainable manufacture of forest products. It is best known by its trade name RoyOMartin. The company is currently operating a plywood and timber mill, and an OSB plant, both in Louisiana. This third facility is operated in Texas by its wholly owned Texas subsidiary, Corrigan OSB LLC.

For more information, visit www.royomartin.com.

TechWood Joins Efforts To Rebuild Indiana Community Landmark With Protective Lumber Treatment

TechWood, a leading developer of protective lumber treatment solutions located in Ft. Pierce, FL, recently joined forces with industry partners to protect and secure a better future for a staple of a small Indiana community.

Located in the heart of Daviess County, IN, The Bargain Center, a family owned grocery store, and a staple of the Daviess community, recently succumbed to a catastrophic fire which devastated the original structure and shook the community with an almost complete loss of the store and nearby warehouse.

No stranger to the devastating effects of fire, TechWood who provides three levels of lumber protection treatment solutions through TechWood 2200, 3300 and 4400, immediately offered to provide treatment of all lumber materials needed for the new construction. Specifically its patented 3300 solution, which provides warrantied protection against mold, rot, decay and termites, and additionally offers Class A fire protection both during and post-construction.

Working together with K&K Industries, a leading manufacturer and builder of truss construction (as well as an industry distributor of the innovative TechWood products) the two teams banded together with local, community and corporate volunteers to treat over 44,000 board feet of lumber and help begin the construction of the new facility with essential fire protection for the future.

“This was an opportunity for us to provide our quality protection for a very special cause.” said Matt Visconti, senior market development manager for TechWood and its parent company Chemical Technology Holding Inc. “We are constantly aware and cognoscente of the risks of fire, both to existing structures and future construction. We wanted to ensure that The Bargain Store was protected properly for the future against all risks and to provide support for an amazing small business to flourish once again.”

TechWood provides treatment services to builders, engineers, architects and contractors nationally through their network of licensed applicators, as well as through their 16,000 square foot treatment facility. For more information on TechWood and TechWood lumber treatments, contact them via email at connect@techwoodtreatments.com, call 772-577-3124 or visit www.techwoodtreatments.com.

KDS Windsor Releases New Advanced Continuous Dry Kiln With Virtual Tour Access

KDS Windsor, located in Hendersonville, NC, recently announced the release of their new state-of-the-art continuous dry kiln (CDK) system designed to deliver an annual production of 150 million board feet.

The new CDK system, incorporating KDS Windsor’s patented DrySpec® and DryTrack® technology, is engineered to optimize drying rates, quality and eff iciency. Featuring a reverse flow double-track design, the kiln integrates several phases—preheating, drying, cooling, equalizing and conditioning—within a single extended chamber. Advanced control and monitoring systems maintain precise moisture and temperature levels, ensuring consistent output and highgrade lumber quality.

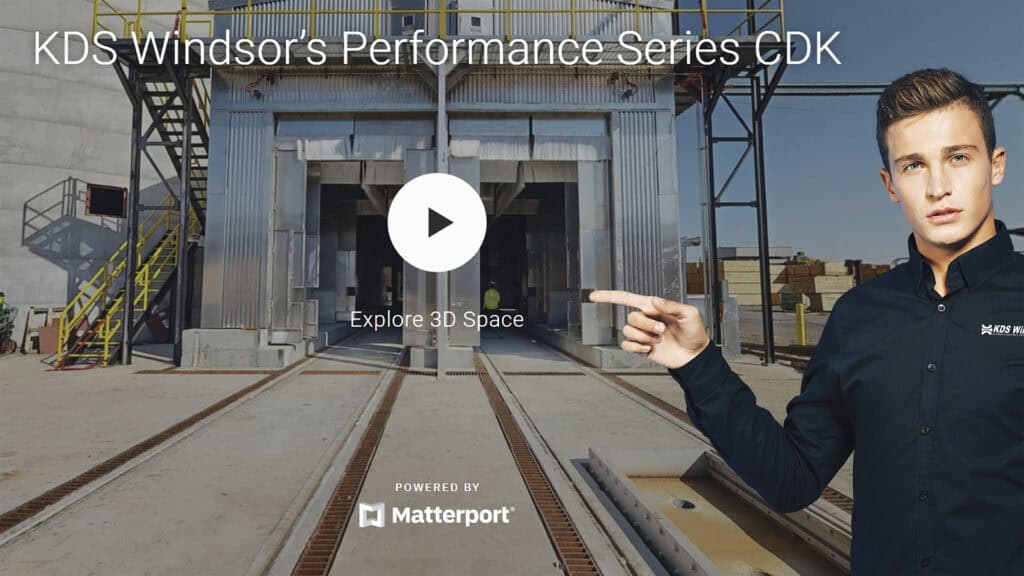

KDS Windsor is offering a Matterport virtual tour of the new CDK system. This interactive tour features a user-friendly menu, allowing visitors to navigate to specific kiln components. Each area has tags, providing pictures, videos and detailed text that highlight the kiln’s advanced features and functionality.

The CDK system has a 50 million BTU green sawdust gasification burner, that generates clean, efficient energy using sawdust, reducing environmental impact and enhancing sustainability. The CDK system is also divided into multiple sections, the energy recovery modules optimize airflow, enhancing heat distribution and significantly reducing energy costs.

“Completing this project underscores our dedication to pioneering kiln technology. We are equally proud to offer a virtual tour, enabling others to experience our innovation firsthand,” said Nick Miletich of KDS Windsor.

For additional information on the project or KDS Windsor’s cutting-edge solutions, please visit www.kdskilns.com.

MiCROTEC And Real Performance Machinery Make Installations At Two Rivers Lumber

As part of a pioneering project in Alexander City, AL, Two Rivers Lumber, with MiCROTEC and Peak North America, Real Performance Machinery’s (RPM) parent company, is advancing the industry through a fully integrated greenfield mill that combines high-tech optimization with precision machinery. Equipped with MiCROTEC’s CT Log and RPM’s ProDog machinery, this sawmill is redefining standards in quality, traceability and sustainability, maximizing lumber recovery with unprecedented accuracy.

The collaboration behind Two Rivers Lumber addresses the industry’s need for sustainable and profitable operations. By leveraging MiCROTEC’s advanced scanning solutions, Two Rivers Lumber makes high quality, datadriven decisions that reduce waste, improve product yield and minimize environmental impact. This technology is resilient in fluctuating markets, enabling mills to consistently maximize output and quality, and operate profitably through the cycle.

This project demonstrates how advanced technology, intelligent design and environmental stewardship can reshape the future of sawmilling. With the CT Log and RPM’s ProDog solutions, Two Rivers Lumber isn’t merely investing in innovation—it’s establishing a new industry benchmark focused on sustainable resource use, product quality and profitability, according to RPM.

By prioritizing high-grade, sustainable lumber processing, Two Rivers Lumber is paving the way for a smarter more resilient lumber industry ready to thrive under any market conditions, according to Two Rivers Lumber. This project serves as a model for sustainable success, proving that high-tech solutions and environmental responsibility can create a bright future for the industry, according to MiCROTEC.

For more information, visit www.microtec.us or www.rpmachinery.com.

Nyle Dry Kilns Completes Kiln Installation For Hammond Lumber Company In Belgrade, ME

Nyle Dry Kilns recently completed the installation of a new state-of-the-art kiln system at Hammond Lumber Company, located in Belgrade, ME. This major upgrade is part of Hammond Lumber’s ongoing efforts to improve operational efficiency and maintain its position as a leading supplier of Eastern White Pine in the region.

The project involved the installation of four Nyle DH Forklift Kilns, each with a capacity of 40,000 board feet, totaling 160,000 board feet across the system. These kilns feature Nyle’s HT54 dehumidification system, which is designed to operate at high temperatures up to 160°F. With 600,000 BTUh LP gas preheat per chamber, this system is optimized for fast and energy-efficient drying, making it an excellent fit for Hammond Lumber’s requirements.

The kilns are designed specifically for drying Eastern White Pine and incorporate cutting-edge features like 36-inch reversing fans, electric-powered exhaust vents and Nyle’s advanced control system. The control system includes a cloud based interface, a 7-inch local control screen interface, digital readouts and remote access capabilities, allowing for seamless operation and monitoring. Additionally, the system’s cloud-based Kiln Connect Control allows for advanced data logging and analysis, ensuring efficient and consistent drying cycles across all four chambers.

Hammond Lumber’s new kiln setup is expected to significantly enhance its overall drying capacity while maintaining energy efficiency and sustainability in line with its commitment to environmental responsibility.

For more than 50 years, Nyle Dry Kilns, located in Brewer, ME, has been a leader in lumber drying technology, providing innovative solutions tailored to the needs of their clients. This latest project for Hammond Lumber Company underscores Nyle’s dedication to delivering high-performance systems that drive success for lumber businesses nationwide.

For more information on Nyle Dry Kilns or to inquire about their services, visit www.nyledrykilns.com.

Continental Underwriters Welcomes Rollins Thompson

Continental Underwriters Inc., located in Richmond, VA, recently welcomed Rollins Thompson as their newest associate production underwriter. Thompson will help with the behind-the-scenes underwriting tasks with client-facing responsibilities. He will work directly with his colleagues to continue to build strong relationships within the industry.

Continental Underwriters Inc. is a Managing General Agency (MGA) and wholesaler providing the forest products industry in North America with a broad range of insurance and risk management solutions designed to safeguard against losses and protect the value of the businesses they insure. Their programs offer a portfolio of insurance coverages for the building materials, lumber, forest products and woodworking industries.

Thompson is an avid outdoorsman whose passion for hunting and fishing led him to pursue Forestry Operations and Business at Virginia Tech.

Outside of work, Thompson can be found hunting, fishing or golfing. His favorite quote from Heraclitus: “No man steps in the same river twice, for it’s not the same river and he’s not the same man.” His belief in constant growth and adaptability fuels both his personal and professional life.

Continental Underwriters is a member of Lake States Lumber Association, Indiana Hardwood Lumbermen’s Association, Appalachian Hardwood Manufacturers Inc., National Wooden Pallet and Container Association, Hardwood Manufacturers Association, North Carolina Forestry Association, Western Wood Products Association, Mississippi Lumber Manufacturers Association, Southeastern Lumber Manufacturers Association, Great Lakes Timber Association, National Hardwood Lumber Association, Virginia Forestry Association, West Virginia Forestry Association and Wood Products Manufacturers Association.

For more information, visit www.contund.com.

NELMA Announces Safety Awards Winners

A total of 18 mills located in the Northeast and Great Lakes provided data from their OSHA Summary of Work-Related Injuries report for calendar 2023 to compete in the 2024 NELMA Safety Award Program.

More than 962 thousand man-hours of Planer Operation work, and 1.09 million man-hours in the Sawmill Operation were reported.

Seven mills employing 420 people with combined operations totaling 899,671 man-hours reported a no loss-time accident-free year in 2023!

Sawmill Operations:

• Division 1 (less than 50,000 man-hours) – Hammond Lumber and Lamell Lumber

• Division 2 (50,000 to 75,000 man-hours) – DiPrizio Pine Sales and Biewer Wisconsin Sawmill

• Division 4 (greater than 100,000 man-hours) – Pleasant River DoverFoxcroft and Irving Forest Products Ashland

Planer Operations:

• Division 1 (less than 50,000 man-hours) – DiPrizio Pine Sales and Hammond Lumber

• Division 2 (50,000 to 75,000 man-hours) – Irving Forest Products Ashland and Milan Lumber

• Division 3 (75,000 to 100,000 man-hours) – Pleasant River DoverFoxcroft and PotlatchDeltic Bemidji

Combined Operations:

• Division 1 (less than 50,000 man-hours) – Hammond Lumber

• Division 2 (50,000 to 75,000 man-hours) – Robbins Lumber – East Baldwin and DiPrizio Pine Sales

• Division 3 (75,000 to 100,000 man-hours) – Hancock Lumber – Pittsfield and Hancock Lumber Madison

• Division 4 (greater than 100,000 man-hours) – Irving Forest Products Ashland and Johnson Lumber

For more information, visit www.nelma.org.

Southern Pine Lumber Exports Continue To Outpace 2023 Through October

Exports of Southern Pine lumber (treated and untreated) are running 13 percent ahead of 2023 through October, according to the most recent data available from the USDA’s Foreign Agriculture Services’ Global Agricultural Trade System, which the Southern Forest Products Association released.

Southern Pine lumber exports were down 23 percent in October over September 2023 and down 16 percent over the same month in 2023.

Mexico leads the way with 133.5 million board feet of Southern Pine lumber imports YTD, up 27 percent compared to the first 10 months of 2023, followed by the Dominican Republic with 81.2 million board feet, up 20 percent over 2023. Jamaica was the third-largest export market through October, up 4 percent at 48.7 million board feet.

Softwood imports, meanwhile, were down 6.2 percent over September to 1.2 million board feet but up 6.2 percent over October 2023.

When looking at the report by dollar value, Southern Pine exports in October were up 7 percent YTD ahead of the same period in 2023 at $183 million, with Mexico leading the way at $51.9 million, followed by the Dominican Republic at $43.1 million and India at $13.9 million. Treated lumber exports, meanwhile, are down a slight 2 percent YTD over 2023 at $113 million led by the Leeward-Windward Islands at $19.2 million, Jamaica with $18 million, and the Dominican Republic at $9 million.

For more information, visit www.southernpine.com.