Roy Anderson Lumber Company Inc. Installed New AI Grading Solution

David Anderson

Roy Anderson Lumber Company Inc., located in Tompkinsville, KY, recently installed a new AI Grading Solution.

Roy Anderson Lumber Company produces 50 million board feet of green and kiln-dried hardwood lumber. They offer their customers rough, straight-line ripped and reclaimed lumber, as well as cross ties, pallet cants, mulch, chips and dust.

“Through our partnership with Neural Grader, we will be implementing a new grading solution at our green sorter over the next several months with the new AI Grading Solution,” said David Anderson, owner of Roy Anderson Lumber Company. The AI Grading Solution will allow Roy Anderson Lumber Company to increase their throughput at their green sorter.

Roy Anderson Lumber Company is also finalizing the addition of a new sawmill, which they plan to be fully operational in 2025. They anticipate that this will add between 7 and 10 million board feet to their production capacity.

Roy Anderson Lumber Company, Inc. was founded in 1950 by Roy Anderson. The company operates two facilities in Tompkinsville, KY, and Eubank, KY, and supplies customers both domestically and internationally.

For more information, visit www.ralumber.com.

John Read Of the Rossi Group Retires, Matt Gauvrit To Replace Him

John Read

John E. Read, Jr. is retiring from the Rossi Group, after a 35-year career with the company, which he started in 1985. Read will be replaced by Matt Gauvrit – who worked for Rossi both as an agent and an export salesman from 1992-2013, before moving back to Europe to work for CIB (hardwood importers).

Read started as Rossi’s exclusive agent in the Iberian Peninsula in 1986, after a spell with Lloyd’s of London and after graduating with a BA in Latin American studies from King’s College, London. In 1994, he was invited to come to the USA and take up the position of vice president for export sales at Rossi, a position he held for 15 years until 2009. He then worked as a consultant, helping clients such as The Malaysian Timber Council, American Hardwood Export Council and GWP – Brazilian decking, amongst others. In 2011 he returned to Rossi as a senior export director, whilst also continuing his business importing Brazilian decking to the USA and Canada.

During his time in the industry, Read said that he has experienced many changes, “I have seen changes across the industry in both technological improvements and market realities. On the export side, for example, the market has gone from being predominantly European, to the dominance of China today. I believe that one of the fundamental challenges ahead, is to continue encouraging the use of American hardwoods in new markets (such as India and Southeast Asia), whilst also stressing the 100 percent sustainable nature of the American forest. Having worked through two mill rebuilding transformations at Blue Triangle and Emporium Hardwoods – I personally have experienced the improved efficiencies of modern mill technology and how important this is to the future of the industry.

Matt Gauvrit

“In my retirement, I am looking forward to dedicating more time to reading, travelling and playing with my 20-month-old granddaughter! I would like to thank everyone at Rossi for their collaboration over the years and I wish the company and Matt a successful future.”

Gauvrit has an ample knowledge of hardwood species (a graduate of the National Hardwood Lumber Association class of 1992); Rossi’s production and export market, having travelled throughout Europe and the Far East. Gauvrit is a father of three and in his spare time enjoys sailing and rugby.

The Rossi Group has been helping their customers navigate the global hardwoods industry for 100 years. With their Emporium mill and kiln facilities, and long-term supply agreements, they are able to offer their customers unique and personal service.

For more information, visit www.rossilumber.com.

Collins Kane Hardwood Completes New Kilns Installation

Collins Kane Hardwood, located in Kane, PA, has recently completed the installation of three new SII 65,000-board-feet package dry kilns. These state-of-the-art kilns are designed to significantly enhance the quality of lumber produced by the facility; the faster drying times and improved ability to hold set temperatures and depressions result in brighter, flatter lumber. This significant investment provides greater energy efficiency and optimizes log usage, aligning with the company’s long-standing commitment to forest sustainability.

“This capital outlay is just another demonstration of Collins commitment to providing quality products, resourced responsibly,” stated Jason Stanley, operations manager of Kane Hardwood.

A long-standing fixture in the hardwood lumber industry, Collins Kane Hardwood operates a sawmill, pre-dryer, dry kilns and a planing mill. The facility processes 18 million board feet of lumber annually and dries 14 million board feet of both domestic and export lumber. Their extensive range of species includes Black Cherry, Hard and Soft Maple, Red and White Oak, Poplar, Ash and Birch.

Collins Kane Hardwood offers a diverse array of products, including rough and surfaced lumber in thicknesses ranging from 5/8 through 12/4, as well as green and kiln-dried lumber in thicknesses of 4/4 through 12/4. In addition to their standard offerings, the operation specializes in custom-sawn timber, railroad ties and switches.

They also provide veneer logs in lengths ranging from 6 to 16 feet. All of the facility’s products are FSC-certified and LEED compliant, as well as Living Futures compliant and FSC-controlled wood. Products are shipped by truck, van or rail.

Founded in Pennsylvania in 1855 by T.D. (Teddy) Collins, the company has maintained a long-standing commitment to land and resource stewardship. Collins manages over 370,000 acres of FSC-certified land across Pennsylvania, Oregon and California. With five manufacturing facilities in the U.S. and a retail yard in California, Collins continues to uphold its reputation as a family-owned forest products company. Their product portfolio includes hardwood, softwood NAF and Declare Label Particleboard, and engineered wood siding and trim.

For more information about Collins and their products, please visit their website at www.collinsco.com.

Mike Schulke Joins Granite Valley Forest Products

Mike Schulke

Granite Valley Forest Products, located in New London, WI, recently welcomed Mike Schulke to their sales/purchasing team. With over two decades of experience in the hardwood lumber industry, Schulke brings his expertise and a customer-focused approach to the team.

Schulke began his career in the lumber industry in 2004 as a lumber grader after earning a vocational degree in NHLA Grading Rules. Over the years, he has held various roles in sales and management, contributing to business growth and strong client relationships. Most recently, Schulke served as sales manager at Tigerton Lumber Co., where he worked on strategic plans and expanded market opportunities. He also worked for Ort Lumber Inc., Wolf River Lumber Inc., Flambeau Inc. and Derby Plastics Ltd.

Schulke holds an associate’s degree in marketing from Fox Valley Technical College, Appleton, WI, and a Plastics Technician Degree from Milwaukee Area Technical College, alongside his NHLA certification.

In his new role, according to a statement from the company, Schulke will focus on strengthening client relationships, enhancing sales strategies and supporting Granite Valley’s commitment to offering the best kiln-dried hardwood lumber to its valued customers.

“I’m excited to join Granite Valley Forest Products and contribute to their ongoing success,” said Schulke.

Outside of work, Schulke is a board member of the Wood Products Manufacturers Association and the Great Lakes Kiln Drying Association. He enjoys skiing, golfing and traveling with his wife, Tina.

For more information, visit www.granitevalley.com.

Lumber Resources Welcomes Alex Gonter-Dray

Alex Gonter-Dray

Lumber Resources recently welcomed Alex Gonter-Dray. Gonter-Dray is a lumber salesman and purchaser that is focusing on the markets of USA, Western Canada and Export. Lumber Resources is located in Quebec City, Quebec, and has a team of eight seasoned sales professionals. The company is partnered with a concentration yard that has 500,000 board feet of kiln capacity and has certified heat treatment for most international markets. Lumber Resources also markets thermally modified hardwoods and softwood lumber for domestic and export customers.

Lumber Resources purchases 6 million board feet and sells 6 million board feet annually in addition to its industrial lumber sales. They offer Yellow Birch, Hard and Soft Maple, White Birch, Ash, Red and White Oak, Aspen and Basswood in thicknesses of 4/4, 5/4, 6/4, 8/4 and 10/4 and in grades Select and Better, Nos. 1 and 2 Common. They are FSC certified for most species.

Gonter-Dray had his first job in the hardwood industry during the summers of high school stacking wood in the dimension plant at Yoder Lumber and during college summers he built log homes and worked in cabinet shops.

Gonter-Dray has degrees in Fine Woodworking and Industrial Technology from the University of Rio Grande and master’s in business administration from Bluffton University, both located in Ohio. Since college he has held positions as a manufacturing engineer for a wooden spool/reel manufacturer and has over 24 years in the hardwood industry with positions of purchasing, sales, director of sales, operations manager and general manager.

Gonter-Dray is active in his community with the Knights of Columbus, volunteering at his church and has held numerous leadership positions for youth sports organizations and school organizations.

Gonter-Dray and his wife Becky have three sons ages 20, 18 and 15. In his spare time he enjoys woodworking, traveling, spending time with family and watching his kids participate in their extracurricular activities.

Lumber Resources is a member of the National Hardwood Lumber Association, Indiana Hardwood Lumbermen’s Association, Canadian Hardwood Bureau and the Canadian Wood Pallet and Container Association.

For more information, email agonterdray@rlumber.ca, call 973-573-7470 or visit www.rlumber.ca.

Midwest Hardwood Company Welcomes Shannon Forrest

Shannon Forest

At Midwest Hardwood Company in Maple Grove, MN, Shannon Forrest is a member of the sales and purchasing team. His responsibilities include managing sales in Southeast Asia and India, and handling kiln-dried purchasing on the United States East Coast. Producing 80 million board feet of hardwood lumber at their three sawmills and two concentration yards, the company has customers worldwide. They offer the following species in thicknesses of 4/4 through 8/4: Hard and Soft Maple, Cherry, Birch, Elm, Beech, Ash, Aspen, Basswood, Walnut, Poplar and Red and White Oak.

Midwest has the ability to develop specialized or proprietary grades for their customers and offers other value-added services such as width sorting, ripping and surfacing. Midwest is also actively producing rift and quartersawn products. Prior to joining Midwest Hardwood in September of 2024, Forrest was employed at Robinson Lumber Company located in New Orleans, LA. He started his career in the forest products industry in 1997 as a trader at Baillie Lumber Co. in Hamburg, NY.

Forrest graduated from Saluda High School in Saluda, SC, before earning a Bachelor of Science degree in Forest Resource Management from Clemson University in Clemson, SC.

His hobbies include hunting, fishing, hiking and boating. He also desires to visit all North American national parks.

He has been married to Amanda Forrest for 26 years and has three sons: Jacob, Caleb and Joshua.

For more information, email shannonforrest@midwesthardwood.com, call 763-226-5085 or visit www.midwesthardwood.com.

Boise Cascade Names New COO Of Building Materials Distribution And Wood Products Divisions

Jeff Strom

Boise Cascade announced Jeff Strom will become its new chief operating officer (COO). This new role will oversee the operations for its Wood Products and Building Materials Distribution (BMD) divisions.

Strom joined Boise Cascade in 2006. He served in many key roles and leadership positions over the years, including vice president and general manager of BMD’s Eastern region. Most recently, he served as the executive vice president of BMD. Strom holds a bachelor’s degree in management from the Georgia Institute of Technology. He serves on the board of trustees for the Boise Valley Habitat for Humanity.

“It is a privilege to lead the operations for our company,” said Strom. “I am excited to start in this new role with a focus on operational excellence, strategic market growth and exceptional customer service. Our integrated business model truly is our competitive edge, and I look forward to continuing to leverage that advantage to create even more opportunities for our company in the future.”

CEO Nate Jorgensen said: “This new addition to our executive leadership team is an important part of our effort to achieve even greater operational excellence across both our businesses. It is also part of our intentional and strategic succession planning process.”

“On behalf of our company and our board, I want to congratulate Jeff on his new role,” said Tom Carlile, board chair. “Jeff is an outstanding leader who personifies our company’s values. His expertise and leadership in this new role will further strengthen our ability to deliver outstanding service and results to our customers, suppliers and shareholders.”

Western Lumber Welcomes Tony Geiger as New Industrial Lumber Sales Manager

Tony Geiger

Western Lumber, based in Medford, OR, recently announced the appointment of Tony Geiger as their new industrial lumber sales manager. Geiger brings more than 20 years of experience in the wood products industry, offering a strong background in leadership, strategic sales and industry expertise.

Geiger’s career includes his tenure as general sales and purchasing manager at Boise Cascade, where he led a high-performing sales team and managed national purchasing contracts. His leadership in coordinating production and building key industry partnerships contributed to the company’s growth and success.

In addition, Geiger brings valuable experience from his time with the family business, Hawkeye Forest Products Inc., where his father-in-law, John Hawkinson, brought him into the industry. Geiger gained deep expertise in hardwood lumber sales from Hawkinson. His combined knowledge of both hardwood and industrial lumber markets will be instrumental in meeting the diverse needs of Western Lumber’s customers.

Geiger and his wife Jennifer are proud alumni of the University of Nebraska, where Geiger competed as a wrestler and Jennifer as a gymnast. They live in Idaho with their three sons and enjoy an active outdoor lifestyle, including mountain biking, wake boarding, snowboarding and snowmobiling.

“With his strategic mindset, passion for excellence and collaborative leadership style, Tony is well-positioned to drive growth and innovation in his new role”, said a company representative. Geiger will be specializing in hardwoods, Pine, Fir and Cedar, to name a few.

For more information, visit www.westernlumber.com.

Boise Cascade’s New BOISE GLULAM®

Pictured is Boise Cascade’s new full width BOISE GLULAM® beams and headers.

Boise Cascade Company, with over 60 locations across the U.S. and Canada, recently announced that their Wood Products division is producing their new full width BOISE GLULAM® beams and headers at their plant in Homedale, ID.

The Wood Products division manufactures high-quality engineered wood products, plywood and lumber for residential, multi-family and light commercial construction needs. According to a company representative, “Our wood products provide strength, stiffness and dimensional consistency through efficient use of raw materials. Customers have access to a suite of software and SawTek automated saw solutions to increase efficiency and productivity. This is all backed by a team of dedicated professionals delivering superior support and knowledge.”

BOISE GLULAM® beams and headers are now available in 3½-inch and 5½-inch full width sizes and can be shipped anywhere in the West.

The Homedale, ID, glulam plant also produces custom beams, headers and columns fit for residential, industrial, or light commercial construction. These products are available for interior and exterior uses and come in lengths up to 76 feet. Stock beams are available in widths of 3⅛-inch, 3½-inch (NEW), 5⅛-inch, 5½-inch (NEW), 6¾-inch and 8¾-inch, and in depths ranging from 6-inches to 24-inches.

The new BOISE GLULAM® beams and headers in full widths are manufactured to create cost-efficiency and versatility in single and multi-family projects. A broader range of glulam widths and depths helps bring value and proven performance to projects, according to the company representative.

The BOISE GLULAM® line aims to reduce labor costs and save time with consistent quality and service.

For more information, visit www.bc.com/ewp/boise-glulam.

Comact Introduces Hybrid Sawline

Simon Potvin

Comact, a global leader in wood processing solutions, proudly announces the launch of its new hybrid sawline. The hybrid sawline combines circular saws, bandsaws, and advanced smart technologies. The system sets a new benchmark for speed, flexibility, and operational efficiency in handling a wide range of log diameters.

Comact’s hybrid sawline is a transformative solution, particularly for southern USA mills, where a broad range of log diameters and highly flexible operations are critical to maximizing results. The sawline’s ability to seamlessly integrate multiple cutting modes including double profiling, quadruple circular cutting, and sideboards splitting—enables mills to produce diverse lumber products on a single line, optimizing recovery and reducing costs.

“We strongly believe that this new sawline design will be a game changer, especially for our southern USA customers,” said Simon Potvin, Comact’s president and CEO. “These mills face unique challenges in processing a wide range of log diameters. The new hybrid sawline provides the flexibility to handle all log sizes on a single line.”

The hybrid sawline is further strengthened by Comact’s Smart Vision system, powered by artificial intelligence.

This advanced technology optimizes log feeding to ensure a smooth and consistent production flow. Complementary features like the Primary Breakdown Closed Loop Smart Tool enhance precision and value recovery, offering sawmills greater efficiency and automated quality control.

The introduction of the hybrid sawline underscores Comact’s commitment to driving progress in the wood processing industry. This launch reflects a century-long dedication to providing solutions that empower sawmills to overcome challenges and achieve sustainable growth.

For over 100 years, Comact has been a leading OEM in high-caliber wood processing equipment, digital technologies, cutting solutions, project services and aftermarket support.

For more information, visit www.comact.com.

Cleereman Makes Installations In Arkansas and New York

Dan Tooke

Cleereman Industries, located in Newald, WI, recently made installations at Westbury Lumber in Red Creek, NY.

Jason Smith of Westbury Lumber oversaw the new installations at the sawmill. Smith purchased a Cleereman LP-42 Lumber-Pro carriage along with a Cleereman Controls 3-D Scanning system.

Cleereman Industries sent four technicians out to remove the old carriage and install the new LP-42 Lumber-Pro carriage.

This project started on Monday morning and had everything ready to go on Thursday afternoon. Cleereman Controls engineers showed up on Thursday afternoon and commissioned the new 3-D Scanning system and the mill dispatching. The mill was ready to run production the following Monday morning.

Dan Tooke, a senior engineer from Cleereman Controls, did sawyer training. According to Smith, the new scanning system has greatly increased his production and the yield out of his logs.

Cleereman Industries also recently made installations at Douthit Tie & Lumber in Camden, AR. They installed a factory remanufacturer LP-48 linear positioning carriage with Cleereman Controls 3-D Scanning along with a new sawyer cab that Cleereman pre-mounted all the controls in to save time installation. A new Cleereman 42-inch Bar Log Turner was also installed.

Cleereman Industries also installed a new Cleereman LP-36 linear positioning carriage with Cleereman Linear Controls along with a new sawyer cab at Valente Lumber in Averill Park, NY. Cleereman pre-mounted all the controls to save time on installation. A new Cleereman 75 HP Hydrostatic Carriage Drive with Cleereman Electric Controls and a dual air bag cable tensioner was mounted onto a new Cleereman Modular Track-Frame was also installed, as well as a new saw husk with top saw.

For more information, visit www.cleereman.com.

PLM Introduces New Leadership

Steve Firko

Pennsylvania Lumbermens Mutual Insurance Company (PLM), the largest mutual insurer dedicated to wood-related businesses, announced several leadership changes and promotions within the company’s executive staff. The changes are part of PLM’s strategy to enhance the organization’s profitability and growth and prepare for the future, while recognizing the changing complexity of the business of insurance.

Rich Hall

A PLM veteran for more than two decades, Steve Firko, chartered property casualty underwriter (CPCU), will assume the role of executive vice president (EVP) and chief operating officer (COO) overseeing all front-line customer-focused operating departments including underwriting, field operations, claims, loss control, marketing, customer service and operations as PLM continues to evolve to meet the market demands of the future.

Firko most recently served as senior vice president (SVP) of business development, loss control and customer service at PLM. His notable career spans nearly 40 years in the industry, including professional and management-level positions at several multinational insurance companies, and board and committee responsibilities at the Pennsylvania Association of Mutual Insurance Companies and the National Association of Mutual Insurance Companies.

Rich Hall, formerly SVP of underwriting, has been appointed as EVP and will assume responsibility for regulatory and government affairs, as well as for special projects critical to PLM’s future growth and profitability.

Steve Hicks

Steve Hicks, CPCU, formerly assistant vice president (AVP) of underwriting, has been appointed as vice president (VP) of underwriting.

Lindsey DiGangi

Lindsey DiGangi, CPCU, formerly AVP of marketing, has been appointed as VP of field operations.

Sean Briscoe

Sean Briscoe, formerly AVP of underwriting, has been appointed as VP of loss control.

Erin Selfie

Erin Selfe, CPCU, formerly VP of information technology, has been appointed as SVP of information technology.

Harold Jamison, JD

Harold Jamison, JD, CPCU, formerly, SVP of government and regulatory affairs and human resources, has been appointed as general counsel.

PLM is a nationally recognized property and casualty insurance carrier serving the lumber, woodworking and building material industries. Backed by 129 years of experience, the Philadelphia, PA-based company protects over 5,000 businesses nationwide with property, general liability, inland marine, business automobile, commercial excess liability and equipment breakdown coverages.

For more information about PLM, please visit www.plmins.com.

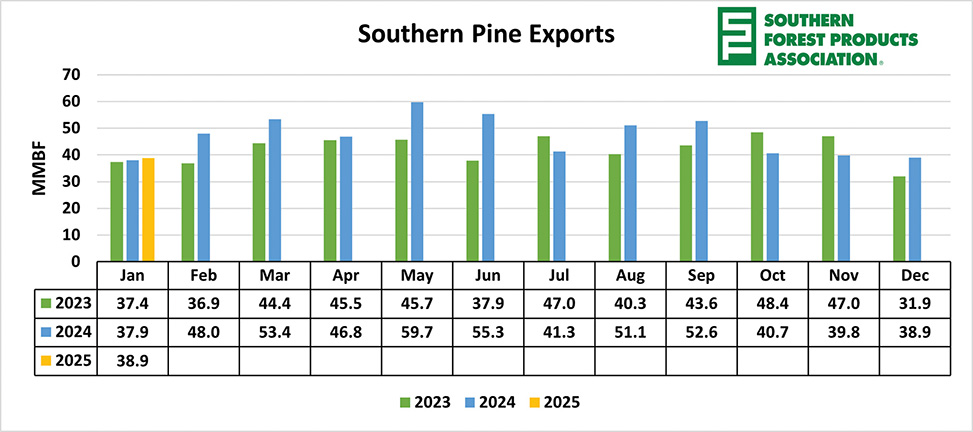

What’s The Story With January 2025 Southern Pine Exports?

According to the most recent data available that was released by the Southern Forest Products Association (SFPA), exports of Southern Pine lumber (treated and untreated) started 2025 up 2.5 percent over January 2024 with 38.9 million board feet but were flat over December 2024, according to January 2025 data from the USDA’s Foreign Agriculture Services’ Global Agricultural Trade System.

Year-end 2024 Southern Pine lumber (treated and untreated) exports hit 565.7 million board feet, up 11 percent over the previous year.

Softwood imports, meanwhile, started 2025 flat compared with the same month a year ago at 1.1 million board feet but up 10 percent from December 2024. Overall, softwood imports ended 2024 down 2 percent over 2023.

When looking at the report by dollar value, Southern Pine exports started the year strong, up 10 percent over the first month of 2024 at $15.6 million. Mexico led the way at $4.1 million, followed by the Dominican Republic at $3.7 million and Canada at $1.7 million.

Treated lumber exports, meanwhile, were down 13 percent to $8.5 million led by the Leeward-Windward Islands at $2 million, the Netherlands Antilles at $1.1 million and the Bahamas with $881,000.

SFPA’s international consultants weighed in with the following key takeaways on Southern Pine lumber (treated and untreated) export numbers among countries reporting more than 1 million board feet of imports in the first month of 2025:

- Mexico remains the largest export market (by volume) of Southern Pine and treated lumber, up 14 percent over January 2024 with 9.9 million board feet of imports.

- The Dominican Republic, the number two importer of Southern Pine, started the year slow, down 8 percent with 6.9 million board feet.

- Canada, which ended 2024 as the number five importer of Southern Pine lumber (treated and untreated), was the number three importer in January, up 91 percent over January 2024 with 3.3 million board feet.

- India posted a slow start to the new year, down 56 percent with 1.5 million board feet.

- Pakistan, which ended 2024 up 68 percent over 2023 with 12.5 million board feet, posted a 53 percent gain over January 2024 with 1 million board feet.

- Exports to China, now the 10th largest importer, started the year above the 1 million board feet mark.

- The following countries in the Caribbean and Central American region, outside of Mexico and the Dominican Republic mentioned above, imported more than 1 million board feet in January 2025:

o The Leeward-Windward Islands: up 16 percent over January 2024 with 36.5 million board feet.

o Jamaica: up 30 percent with 2.1 million board feet.

o The Bahamas: up 19 percent with 1.9 million board feet.

o Netherland Antilles: up 98 percent at 1.2 million board feet.

For more information, visit www.southernpine.com.