By Matthew Fite

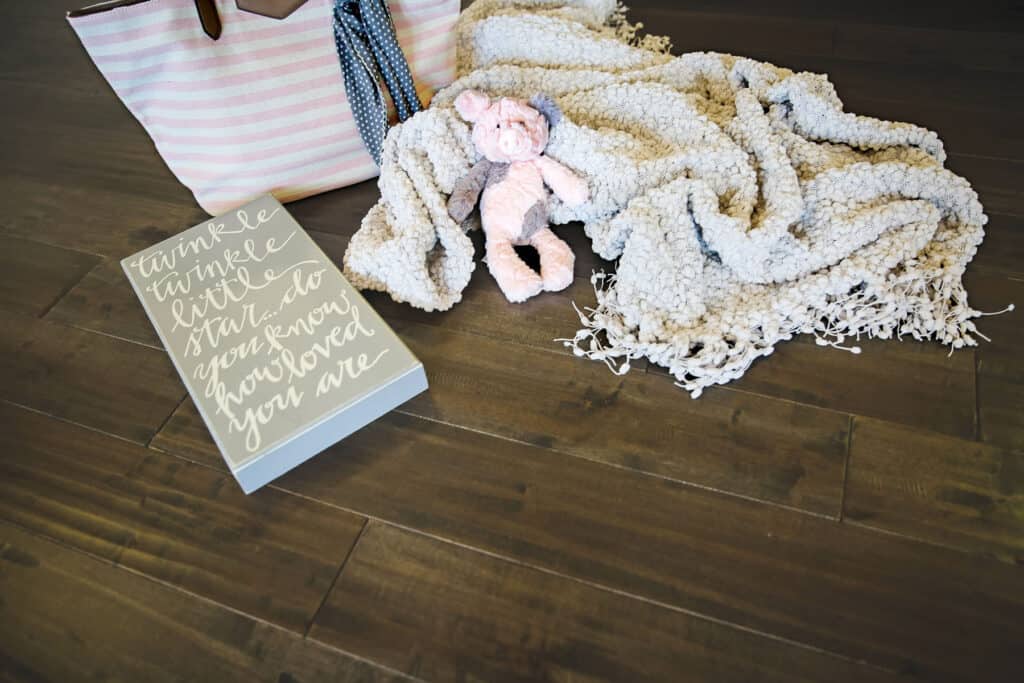

Peshtigo, WI—Aacer Flooring, based here, manufactures Hardwood floors on which elite athletes sprint and make quick stops, their sneakers squeaking audibly. The company also manufactures residential Hardwood flooring, on which babies crawl silently.

Ray Webb, general manager, said that Aacer has focused on becoming a “one-stop shop for anything in Hardwood flooring.” As for the two types of flooring produced, “They’re kind of two different sales channels,” Webb noted. “If we looked at the commercial side with the sports, we’re very well known around the country for that. On the residential side, through wholesale distribution, we’re also fairly well known for the prefinished engineered in that wholesale distribution arena.”

Aacer Flooring’s 350,000 square foot manufacturing facility is located in Peshtigo, WI.

The company purchases approximately 16 million board feet of Hard Maple, Red and White Oak, Birch, Ash, Cherry and Hickory in No. 2 and No. 3A. Primarily, their wood comes from Michigan, Wisconsin and southern Ontario. “It does lend itself to be more structurally stable because of the slow growing seasons so your growth rings are tighter together; your cell structure is a little bit tighter together,” Webb observed. “You don’t get as much variation in climates that fluctuate greatly. Another advantage is: it’s a more consistent color throughout the product.

Aacer ships its flooring worldwide.

“We buy primarily green lumber,” Webb stated. “We have 1.2 million board feet of kiln capacity on site.” Aacer cuts these raw materials into Northern Hardwood Flooring (both solid unfinished and solid prefinished) and engineered flooring (both unfinished and prefinished). Aacer employees cut the wood into three primary thicknesses: ¾ inch, 25/32 and 33/32.

Products manufactured by Aacer include high-performance sport floors.

“We’re a little unique in the fact that we have the two different business segments,” Webb remarked. “Typically, what you see is, someone is either into that distribution residential market or they’re into the sports market, but there’s not many that are into both markets.” Aacer is known for consistent quality in both segments. Webb stated, “I think probably our most unique thing that we do, that most other manufacturers don’t, is our internal quality control personnel and process. It’s ongoing. It’s constant training. You have folks on the floor that do nothing but follow up with dimension checks and grade consistency and then work with the actual operators and graders on an individual basis all shift long to keep a consistent product coming out.”

Aacer may have two markets but it has one manufacturing location, a 350,000 square foot facility in Peshtigo, WI. This facility was built in 1998. This is where kiln-drying and cutting of the lumber takes place. The most recent addition to it was in 2016 when an engineered line was added.

Aacer manufactures solid and engineered prefinished flooring.

This kiln drying and cutting of the lumber provides “more quality control over it,” Webb observed, “so that we have a consistent product coming out.” He stated that “if you buy kiln-dried lumber from 30 different sources, your moisture content is never going to be consistent. If you do it on site, you can have a consistent moisture content and then you have control of the quality from beginning to end.” Equipment in Aacer’s plant comes from 50 different manufacturers. The primary material handling equipment is OSI. Rip saws are from Lico; moulders are from Hasko. End matchers are from OSI.

The company has 183 employees. About 160 of these are involved in kiln drying and cutting the lumber into flooring. Jerry Ort is the owner. Matthew Gerard is controller. And Laura Thomson is human resource manager.

Aacer offers prefinished flooring in smooth, wirebrush and scraped textures.

Aacer was started in 1998. In the downturn of 2009-11, the company employed about 96 people. With the current market, Aacer expects to have 220 to 225 employees by the end of 2020. On the sports side, Aacer increased its market share by 50 percent from 2011 to 2018. On the residential side in 2019, the company increased its business 45 percent over 2018 in prefinished flooring.

Aacer Sports Flooring supplies Hardwood flooring and sub-floor systems to the sports and recreation industry. Aacer also provides a variety of synthetic flooring options. Their floor systems focus on safety and performance and can be found in gymnasiums, multi-purpose rooms, weight rooms, dance and aerobic studios and indoor tracks. Aacer provided an athletic floor for the University of Miami. They have provided several floors at Penn State University and for a good number of other Division I universities.

environmentally, customer- and employee-friendly.

Aacer comes out with new lines in its residential side and in the sports side annually. In early 2020, the company launched a new family of subfloor systems in the sports side. In the future, Aacer plans to introduce technological advances in its manufacturing.

Aacer is a member of the Maple Flooring Manufacturers Association, the Lake States Lumber Association, the National Wood Flooring Association, the American Sports Builders Association, the US Green Building Council, the FSC/Rainforest Alliance (Forest Stewardship Council), the American Institute of Architects, the World Squash Federation, the Federation of International Basketball Association and the Badminton World Federation.

For more information, go to www.aacerflooring.com.