Our Company History

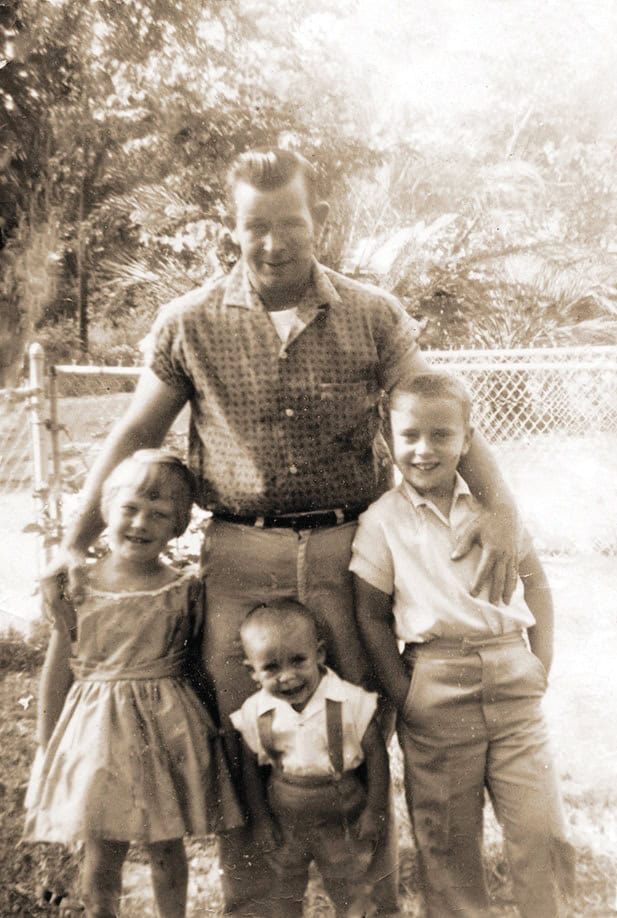

Gene Hurst, Teri, Hayward

and Tommy Hurst in 1963

We’ve come a long way since our first shop and we are now housed in a manufacturing facility and campus that encompasses 48-plus acres, allowing us to manufacture a large variety of boilers to meet the diverse conditions and requirements of customers around the world.

Established in 1967, Hurst Boiler has been an all-American manufacturer of industrial boilers with a reputation for quality work at reasonable prices. In 1970, we built a larger shop to accommodate our customers’ needs for fast and efficient work. In 2007, we completed a large expansion doubling our manufacturing space. Continued strong sales have now prompted further construction, bringing the total size of the manufacturing facility to 350,000-plus square feet. With the current expansion, Hurst Boiler added several dedicated manufacturing lines and now maintains over 275 employees at full production capacity.

Sons Tommy and Hayward Hurst had been trained by their father from an early age and soon they joined their parents in servicing more customers. Both are mechanically adept and within a few short years, through a philosophy founded in innovation, helped expand Hurst Boiler to become a complete boiler manufacturing and design company that now serves a global market.

Today, Tommy Hurst is the president and Hayward Hurst is the director of field installations. Daughter Teri Hurst White serves as the corporate affairs secretary and the youngest son, Jeff Hurst, is the director of marketing. Several grandchildren and family members have also chosen to make Hurst Boiler their life’s work.

We are as committed today as we were in 1967 to providing the highest quality products and services at the most reasonable prices. It is our customers who motivate us to be the best in our industry.

Hurst Boiler & Welding Co. Inc., corporate headquarters shown here, is located in Coolidge, GA.

Gas, Oil, Solid Fuel, Solid Waste, Biomass, Wood, Coal And Hybrid Firetube And Watertube Steam And Hot Water Boilers

Established in 1967, Hurst Boiler has been an all-American manufacturer of industrial boilers: gas, oil, solid fuel, solid waste, biomass, wood, coal and hybrid firetube and watertube steam and hot water boilers.

Packaged steam, hot water, multifuel and biomass boilers 6 to 2000 HP, with pressures up to 450 PSI. Hurst is a custom PLC boiler controls and accessories. Low NOx modular boilers and burner configurations are available for all models. Watertube boilers: series O, A, D and Flex with sizes from 10,000 to 150,000 PPH, pressures to 1000 PSI, with various fuel and auxiliary options are available. Modular biomass thermal to electric cogeneration systems are offered from 250 kWe to 15 MWe packages. Hurst Boiler manufactures seven different types of biomass stoker/gasifiers, using 2,000 different types of biomass fuels.

Hurst Boiler proudly offers major repairs as well as service and preventative maintenance of Hurst Boiler’s steel boilers, ASME welding, “R” and “PP” stamps, refractory and tube repairs. Hurst Boiler stocks a large inventory of boiler parts including pollution control systems and exchangers, controls, forced draft burner parts, feedwater tanks, water softeners, chemical feed systems, castables, refractories and insulations. Parts and service distributor/dealer network available worldwide.

Parts, service and maintenance are available via Hurst Boiler After Market and Service departments. We are committed to providing you with the best service and parts in the industry. We stock replacement parts for our boilers and other major competitors’ boilers as well. Our 40-plus acre manufacturing facility in Coolidge, GA, supports our parts center with the latest technology and competitive rates, offering shipping with all major carriers for speedy delivery of critical parts to your facility in a timely fashion.

Hurst Boiler is housed in a manufacturing facility and campus that encompasses 48+ acres in Coolidge GA, allowing the company to manufacture a large variety of boilers to meet the diverse conditions and requirements of customers around the world.

And It Doesn’t End There

Having grown both our family and our business here in Coolidge and Thomasville, GA, Hurst Boiler is deeply proud and committed to being involved in all aspects of the community at large. We sponsor trade days with area colleges and trade schools and participate in employment fairs and manufacturing competitions. As the Thomasville chamber and business development councils increased their outreach, we have continually looked to keep pace and be involved.

Georgia Governor Brian P. Kemp announced the ‘Georgia Made’ program at the Hurst Boiler factory surrounded by Hurst employees and representatives during his statewide tour in 2019.

Community. We’re Big Fans

With humble beginnings in the Bottom, West Jackson Street corridor of Thomasville, GA, Hurst Boiler never forgot “where they came from,” and made the pivotal decision in 2015 to join forces with Thomasville Center for the Arts by underwriting the support of a vacant lot on West Jackson Street.

The Center created multi-disciplinary experiences in the heart of our historic downtown to challenge our community to re-think the way they perceive art and one another. By bringing unexpected ideas to life, we knew we could actively engage our neighbors and create a strong sense of place.

The Center in partnership with Hurst Boiler made it our mission to encourage artists to create and leverage their art to CONNECT PEOPLE and MAKE A DIFFERENCE. These measures helped Thomasville Center for the Arts transform our downtown into a distinctive, desirable place to live, while engaging visitors and our neighboring pocket communities.

Thomasville Center for the Arts in partnership with Hurst helped transform the downtown public art in “The UnVacant Lot”.

Highlights

Today, the Thomasville community has embraced public art in “The UnVacant Lot,” as a conversation-starter that has led to collaborative projects designed to address some of our communities most critical needs. Based on our track record and clear understanding about how public art changes communities, Thomasville Center for the Arts and Hurst Boiler is leading the development for a downtown public art presence that will drive our creative economy and tourism. Hundreds of visitors walk into the lot on a daily basis.

Progress

It’s been a team experience. Hurst Boiler is focused not only on stability and growth for future generations, but also on the quality and sustainability of the products we sell. By maintaining the highest standards of materials and processes, Hurst Boiler can be depended on to provide the highest quality equipment and services to our customers, suppliers and communities for generations to come.

GA Made Designation

Hurst Boiler is proud to have earned the Georgia Made Designation.

Georgia Gov. Brian Kemp created the “Georgia Made” program to encourage manufacturers to promote the state on their products.

Kemp announced the program in 2020 at the state Capitol, surrounded by representatives of 11 companies whose factories he visited during a statewide tour last fall.

The Georgia Department of Economic Development will begin certifying products as Georgia-made later this year, giving the stylized peach logo to any product at least 50 percent made in the state.

“I hope each of the companies here will place it on your products as a badge of honor,” Kemp said. “The world-class products manufactured by these Georgia Made companies are a large part of what solidifies Georgia’s position as the top state for business. These companies have created greater opportunities for hardworking Georgians in every corner of our state. Together, we will continue to let the world know that the Peach State is open for business.”

Committed To Georgia. Committed To Excellence

Beginning in 1967 Hurst Boiler expanded its investment in Georgia by establishing Hurst Boiler & Welding Co. Inc. a state-of-the-art production facility in Coolidge. Since then, we have helped create hundreds of jobs in Coolidge, Thomasville and the surrounding areas, and produced thousands of industrial boilers, which can be found facilitating business operations across the U.S. and the world. We owe so much of our success to the people who work closely with Hurst Boiler and the state of GA. The quality of our plant and its people are the two most important reasons why we are considered one of the best Global Brands in industrial boiler manufacturing. We’re proud to call Georgia home and look forward to continuing our longstanding relationship together.

For more information, email info@hurstboiler.com or visit www.hurstboiler.com.